Starting Up the Welding Torch Service Station

General

NOTE!

If wetting agent has not been applied to the inside of the welding torch, this may

lead to the permanent contamination of the welding torch when welding begins.

Always wet the inside of the welding torch with the manufacturer's "Robacta Reamer"

parting agent before starting an automatic application.

To achieve optimum cleaning results, observe the following points:

-

Always wet the inside of the welding torch with parting agent

-

Adhere to the specified cleaning procedures

-

Adhere to the specified cleaning positions

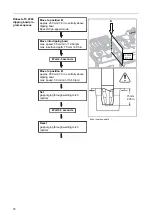

Opening the

Welding Torch

Service Station

If the welding torch service station is equipped with an optional fieldbus as a robot con-

trol unit connection, the service station for connecting the robot control unit and for fault

diagnosis of the fieldbus must be opened as follows:

*

4

3

2

1

3

3

2

2

1

Remove collecting tray

2

Remove three TX25 screws on the left

3

Remove three TX25 screws on the

right

4

Remove frame

* Position of the bus coupler

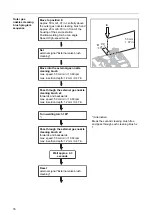

Requirements for

Starting Up

The following requirements must be met in order to commission the cleaning device:

-

Securely bolt the welding torch service station to the surface

-

Any available optional equipment installed on the welding torch service station, sup-

plied with compressed air and connected to the grid if necessary

-

Compressed air supply to the welding torch service station established

-

Cleaning device connected to the robot control unit

Starting Up the

Welding Torch

Service Station

1

Check whether all optional equipment is correctly connected to the welding torch

service station

2

Connect welding torch service station to the robot control unit

max. length of the control cable = 30 m

3

Establish electrical supply to the optional equipment

max. length of the mains cable = 30 m

4

Establish compressed air supply

max. length of the compressed air supply line = 30 m

62

Summary of Contents for Robacta TSS /i

Page 2: ......

Page 11: ...General 11 ...

Page 12: ...12 ...

Page 18: ...18 ...

Page 19: ...Operating controls connections and mechanical components 19 ...

Page 20: ...20 ...

Page 32: ...32 ...

Page 33: ...Installation and Startup 33 ...

Page 34: ...34 ...

Page 61: ...12 12 12 Connect the compressed air supply 61 EN US ...

Page 64: ...64 ...

Page 65: ...Cleaning Program Sequence 65 ...

Page 66: ...66 ...

Page 68: ...A B C D E F G 68 ...

Page 79: ...Reset external signal Internal valve brush cleaning 79 EN US ...

Page 84: ...Reset external signal Cut wire electrode End of the cleaning process Welding 84 ...

Page 85: ...Troubleshooting Maintenance and Disposal 85 ...

Page 86: ...86 ...

Page 97: ...Appendix 97 ...

Page 98: ...98 ...