28

PB

Metering Device - Capillary Tube Systems

All units are equipped with capillary tube metering devices. Checking for restricted capillary tubes.

1. Connect pressure gauges to unit.

2. Start the unit in the cooling mode. If after a few minutes of operation the pressures are normal, the check valve and the

cooling capillary are not restricted.

3. Switch the unit to the heating mode and observe the gauge readings after a few minutes running time. If the system

pressure is lower than normal, the heating capillary is restricted.

4. If the operating pressures are lower than normal in both the heating and cooling mode, the cooling capillary is restricted.

Check Valve

A unique two-way check valve is used on the reverse cycle heat pumps. It is pressure operated and used to direct the flow of

refrigerant through a single filter drier and to the proper capillary tube during either the heating or cooling cycle.

NOTE:

The slide (check) inside the valve is made of teflon. Should it become necessary to replace the check valve, place a wet

cloth around the valve to prevent overheating during the brazing operation.

CHECK VALVE OPERATION

In the cooling mode of operation, high pressure liquid enters

the check valve forcing the slide to close the opposite port

(liquid line) to the indoor coil. Refer to refrigerant flow chart.

This directs the refrigerant through the filter drier and

cooling capillary tube to the indoor coil.

In the heating mode of operation, high pressure refrigerant

enters the check valve from the opposite direction, closing

the port (liquid line) to the outdoor coil. The flow path of

the refrigerant is then through the filter drier and heating

capillary to the outdoor coil.

Failure of the slide in the check valve to seat properly in

either mode of operation will cause flooding of the cooling

coil. This is due to the refrigerant bypassing the heating or

cooling capillary tube and entering the liquid line.

COOLING MODE

In the cooling mode of operation, liquid refrigerant from condenser (liquid line) enters the cooling check valve forcing the

heating check valve shut. The liquid refrigerant is directed into the liquid dryer after which the refrigerant is metered through

cooling capillary tubes to evaporator. (Note: liquid refrigerant will also be directed through the heating capillary tubes in a

continuous loop during the cooling mode).

HEATING MODE

In the heating mode of operation, liquid refrigerant from the indoor coil enters the heating check valve forcing the cooling

check valve shut. The liquid refrigerant is directed into the liquid dryer after which the refrigerant is metered through the

heating capillary tubes to outdoor coils. (Note: liquid refrigerant will also be directed through the cooling capillary tubes in a

continuous loop during the heating mode).

COMPONENT TESTING

Hermetic Components Check

BURN HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with a torch.

Failure to follow these procedures could

result in moderate or serious injury.

WARNING

WARNING

CUT/SEVER HAZARD

Be careful with the sharp edges and corners.

Wear protective clothing and gloves, etc.

Failure to do so could result in serious injury.

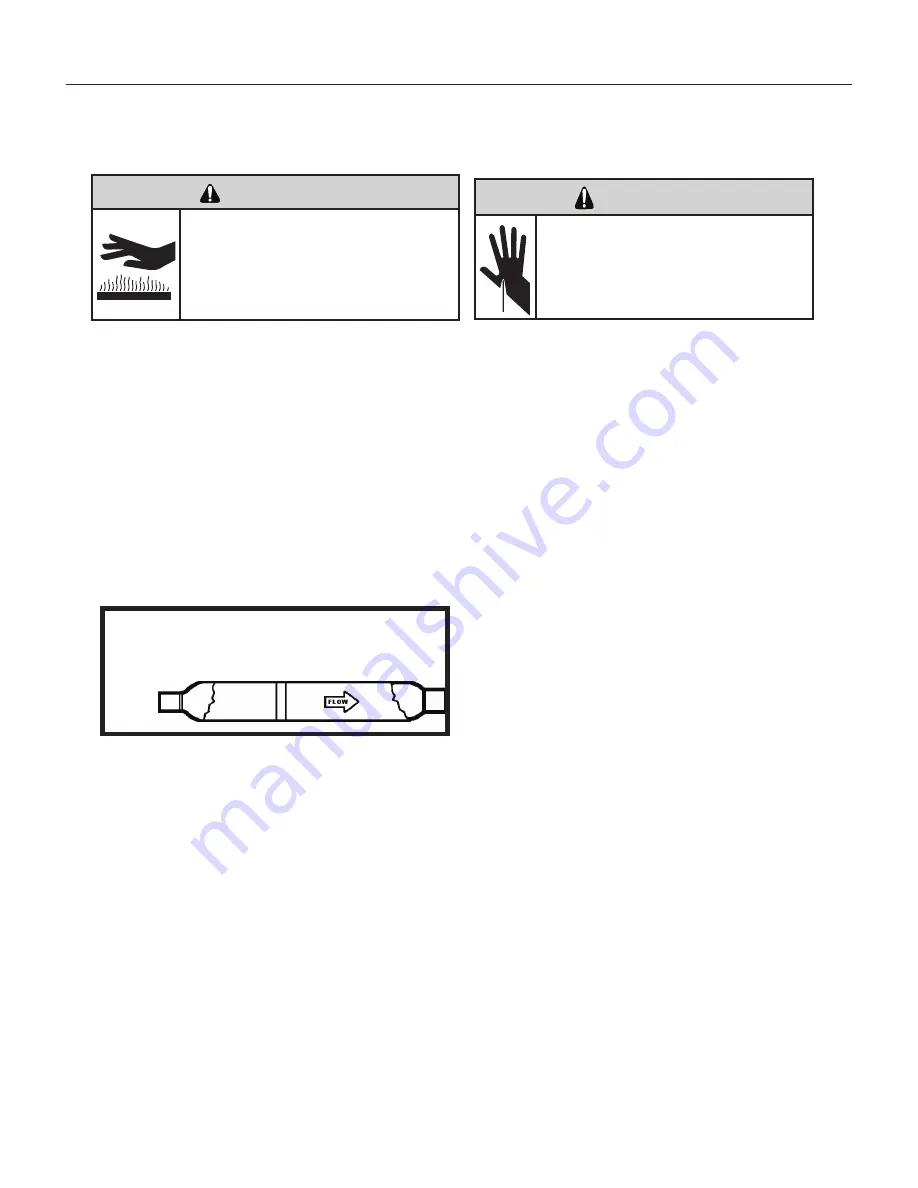

One-way Check Valve

(Heat Pump Models)

Figure 701 (Check Valve)