210.100-IOM (JUL 2018)

Page 41

ACUAIR

®

HYGIENIC AIR UNITS

MAINTENANCE

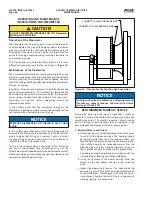

2. Infrared Temperature Scanner –

Focus the scanner on the tip of the temperature sensor.

Use the temperature reading on the infrared scanner to

calibrate the AcuAir controller input channel.

Submerge Tip in Ice Bath or

Focus Infrared Scanner Here

Figure 48 – Temperature Sensor

UNIT CLEANING AND SANITATION

The AcuAir hygienic unit requires frequent and thorough

cleaning. Your chemical supplier should be consulted when

picking the proper cleaning chemicals.

CAUTION

DISCONNECT ALL ELECTRICAL POWER BEFORE CLEAN-

ING THE UNIT.

Before cleaning, any capped drain pipes should be uncapped,

and motors should be draped with plastic. During cleaning,

the following components should

NOT

be directly sprayed

with water: Motors, Damper Motors, Bearings, Pitot Tubes,

Filters, and Electronic Sensors.

NOTICE

High pressure water has the potential to dislodge caulk

and sealing putty. It is important to thoroughly inspect

all seam caulking and electrical conduit sealing putty

following a sanitary wash down.

WHITE RUST AND WET STORAGE STAIN OF

GALVANIZED STEEL

Many AcuAir rooftop units are purchased with simple mill

galvanized exterior finish.

Galvanizing is the result of applying

a coating of zinc to sheet metal. The zinc coating is intended

to provide long lasting protection of the underlying steel.

Raw zinc, by nature, is reactive and tends to corrode quite

readily when exposed to moisture. To develop the long lasting

protective quality for which it is applied, the zinc must undergo

a sequence of chemical reactions. First the zinc must react

with oxygen to create zinc oxide. Second, the zinc oxide reacts

in the presence of moisture to create zinc hydroxide. Finally,

the zinc hydroxide reacts with CO

2

within dry air to create a

thin layer of impermeable zinc carbonate. The carbonate layer

is what forms the long lasting passive coating that drastically

slows down any further reaction of the zinc and provides

corrosion protection of the underlying steel. When properly

formed, the zinc carbonate layer is identified by a dull-gray

appearance.

If the zinc coating of new galvanized material is prevented

from thoroughly drying and receiving exposure to CO

2

the

passive carbonate layer is not formed. If the Zinc hydroxide

to carbonate reaction does not take place, excessive zinc

hydroxide accumulates as a layer of soft, white, fluffy product

of corrosion. Instead of being dense and protective, this

powdery substance is porous and non-protective of the

substrate material. When the zinc oxide-hydroxide reaction

is allowed to progress, it can rapidly degenerate the substrate

layer of zinc. This buildup of zinc hydroxide is known as white

rust. It is created by small localized corrosion cells and will

appear as stain patterns in contrast to the uniform dull-gray

zinc carbonate layer mentioned previously.

Addressing A Light Coating Of White Rust

Also Known As

Wet Storage Stain

Occasionally AcuAir units may arrive on site with patches of

visible zinc hydroxide deposits. In other cases white patches of

the deposit may become visible shortly after arrival. In either

case, because the AcuAir products are built and are shipped

very shortly thereafter, these hydroxide zones are quite young

and any deterioration of the underlying zinc is insignificant.

In most cases the zinc hydroxide is so light it will erode over

time and the desirable zinc carbonate layer will form naturally

with the rain and drying cycles. However, in a few instances

and for cosmetic reasons it may be necessary to intervene

and expedite the passivation process.

Light coatings of zinc hydroxide can be removed using

readily available cleaning products. A study presented by

the American Galvanizers Association (AGA) suggests the

following five

cleaning products to successfully handle the task.

Available at any local grocery store:

• Lime Juice

• White Vinegar

Commercial Cleaners tested:

• Picklex 10G (best solution according to the test – only

available direct from the manufacturer)

• CLR

• Navel Jelly Rust Dissolver (not recommended for heavy wet

storage stain)

Cleaning White Rust

1. Use a nylon bristle brush to apply one of the cleaners to

the affected area.

2. Thoroughly scrub the surface using the nylon bristle brush,

applying water as necessary.

3. Finally, rinse with plain water to completely remove all

traces of the powdery hydroxide as well as the cleaner.

4. Allow the cleaned surface to dry completely.

The drying process facilitates the formation of the passive zinc

carbonate boundary layer that will mature over time with the

naturally occurring rain and dry cycles.

Summary of Contents for AcuAir

Page 54: ......