210.100-IOM (JUL 2018)

Page 15

ACUAIR

®

HYGIENIC AIR UNITS

INSTALLATION

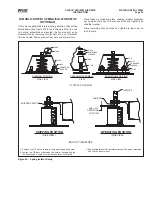

INSULATION OF THE BASE RECONNECT SEAM

OF AN ACUAIR PERFORMANCE SERIES UNIT

When two AcuAir unit sections are drawn together the base

channels of the two sections form an uninsulated cavity that

under certain conditions could produce condensation. AcuAir

provides a ship loose foam insulation kit to fill this cavity as

part of the reconnect procedure.

On the Performance Series air units this insulation must be

injected from underneath the unit after the sections have

been securely joined.

Follow the instructions in the section "FOAM KIT 15 USE

GUIDELINES" on page 21 for preparing the two part foam

mixture and the injection kit. Take special note of the 30

second inactivity limit after which the injection nozzle may

become permanently clogged.

Foam should be injected into the cavity at a rate of 3 - 4

bd-ft per linear foot of seam. This will mean a 15 bd-ft can

of expanding foam will fill between 4 - 5 linear ft of AcuAir

reconnect seam.

INTERNAL RECONNECT

(AcuAir Performance Series Only)

.25 MINIMUM DIA. PARALLEL CONTINUOUS BEADS OF

POLYURETHANE CAULKING REQ’D (BOTH FACES OF SPLIT)

PRIOR TO REASSEMBLING

RECONNECT, HOUSING, AND

HARDWARE NOT SHOWN THIS SIDE

FOR CLARITY

HOUSING

Foam Injected

From Underneath

Figure 12 – Foam Injection Underneath Base Assembly Attachment - Relates to AcuAir Performance Series Unit Only

NOTICE

INJECT THE FOAM INTO THE OPEN SEAM AFTER THE

AIR UNIT SECTIONS HAVE BEEN SECURELY

RECONNECTED.

NOTICE

IF FOAM DISPENSING HAS STOPPED FOR MORE THAN

30 SECONDS, REPLACE THE NOZZLE WITH THE

EXTRA PROVIDED.

Summary of Contents for AcuAir

Page 54: ......