25

ELECTRICAL CONNECTION

6.1.

Connecting the unit to the power supply

Unit connection to the to the power supply must be carried out only by qualified

personnel.

Note the following before connecting the unit:

•

Applicable local electrical safety regulations.

•

The power supply voltage and frequency must match the specifications on the

technical data sticker.

•

Do not connect a damaged unit or damaged parts (such as electrical cables) to

the power supply.

•

Only connect the unit to a mains circuit with protective grounding.

•

Do not use extension cords or multiple socket strips.

7.

DRAINAGE

7.1.

Drainage system

Freezer Vega Space QB Freezer to be equipped with suitable drainage system. The

condensate can be drained to the tub trough the drainage siphon.

Also, condensate drainage can be connected to the common sewerage system.

Drainage connection points are indicated in the furniture layouts. It is necessary to

check the condensate collection tub to prevent it from the entry of food remains,

sand or larger dust particles.

8.

MAINTENANCE, DEFROSTING, CLEANING

8.1.

Maintenance

In general, this equipment does not need any maintenance. However, they need

defrosting and cleaning as described in further sections.

8.2.

Defrosting

Warm ambient air can get into self-service showcases. It is particularly probable when

the showcase is without doors, or its door is left open. Due to it, evaporator can frost.

Evaporators must be regularly defrosted in accordance with programs set in the

control. During the defrosting refrigeration is not run.

Evaporators of high-temperature cabinets can be defrosted using recirculation air

flows. Evaporators of medium- and low-temperature can be defrosted using electrical

heating elements.

The ventilator operation during defrosting is described in the technical characteristics.

Summary of Contents for VEGA SPACE QB

Page 1: ...OPERATION MANUAL SERVE OVER VEGA SPACE QB FREEZER...

Page 6: ...6 1 2 Dimensions Fig 2 Dimensions of Vega Space QB Freezer LU...

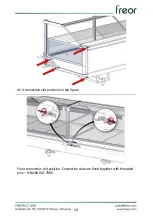

Page 13: ...13 Install the plastic legs Lower the serve over...

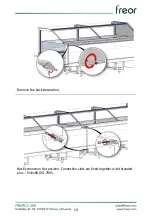

Page 17: ...17 Push the serve overs together With help of a level check if both serve overs are horizontal...