DFA400 Rev0708

10

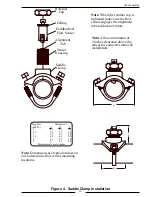

Install Flow Sensor

There are several ways to install paddlewheel type flow sensors. Mounting options

include saddle clamps, weldments, pipe tees, and special adapters. Each mount meets

a particular plumbing requirement.

Flow sensors are interchangeable. It is recommended to check display accuracy if

sensors are swapped and calibrated when necessary.

The maximum flow sensor pressure is 600 PSI.

Flow Sensor Location

Locating the flow sensor in the plumbing system is critical. The flow of water

at and around the sensor must be laminar, or smooth, to ensure accurate flow rate

measurement. There must be enough straight pipe before the flow sensor for the water

stream to stabilize into a uniform flow. Guidelines for selecting flow sensor locations

are outlined in Figure 3.

Turbulent Water

When the flow sensor is mounted after an area in the plumbing that tends to increase

water stream turbulence (a valve, increase in pipe diameter, etc.), it is critical that steps

are taken to stabilize the flow. When a pipe is reduced in diameter, the water stream

tends to be squeezed into a more uniform flow. This can help stabilize flow when there

is not sufficient straight pipe up stream.

Linearizer Feature

This meter features a Linearizer function in the calibration programming. This

function should be used when the flow sensor is installed in a plumbing location

where flow is not linear. It corrects for nonlinear flow by calibrating the display at

multiple flow rates (up to 9). This provides more accurate flow rate readings. (Refer

to Calibration Section.)