Pan

Tilt System

Users Manual, Rev. 1.0, May 2020

52

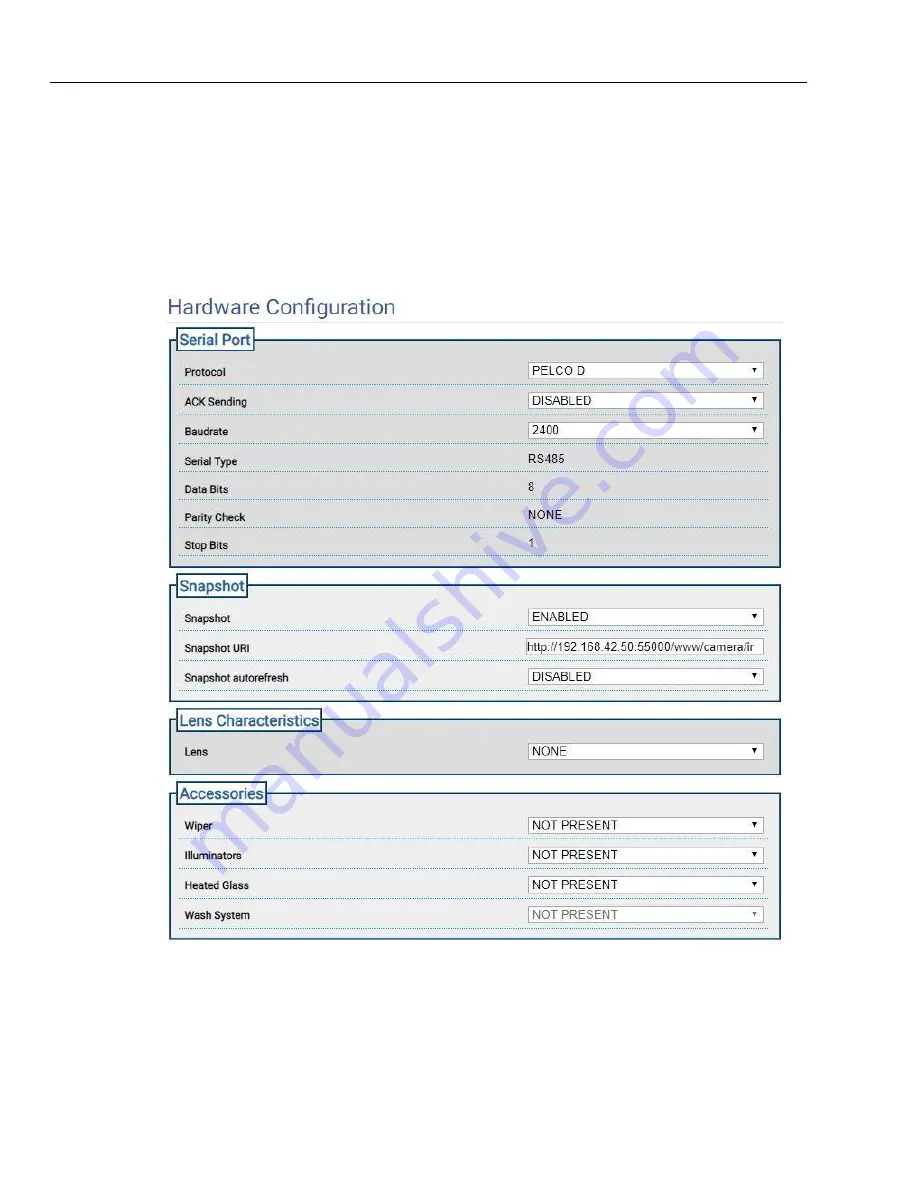

7.2.16 Hardware Configuration

The submenu Snapshot is the only relevant one for the user. To establish the communication and to get an image

stream from the camera enable the item Snaphot and provide the following instruction:

http://

192.168.42.50

:55000/www/camera/ir

whereby

192.168.42.50

stands for the current IP address of the camera and must be adapted accordingly.

Figure 7-16: Hardware Configuration Page

7.2.17 System Log

The System Log menu can be used to view the history of events. The system can detect different types of status

changes. The buttons below the log window allow you to select the filter by level of criticality.

•

Error Level:

Displays only critical errors.

•

Warning Level:

Displays errors that could compromise proper functioning.

•

Download Files:

Allows you to download the log files.

Summary of Contents for Pan Tilt System

Page 5: ......

Page 21: ...Technical Data Dimensions 21 2 2 4 Dimensions Figure 2 2 Dimensions ...

Page 32: ...Pan Tilt System Users Manual Rev 1 0 May 2020 32 Fully assembled camera ...

Page 41: ...Pan Tilt Head Installation Fixing 41 5 Figure 5 10 Fixing of Upper Body and Base ...

Page 56: ...Pan Tilt System Users Manual Rev 1 0 May 2020 56 ...