9100A-017

7-19

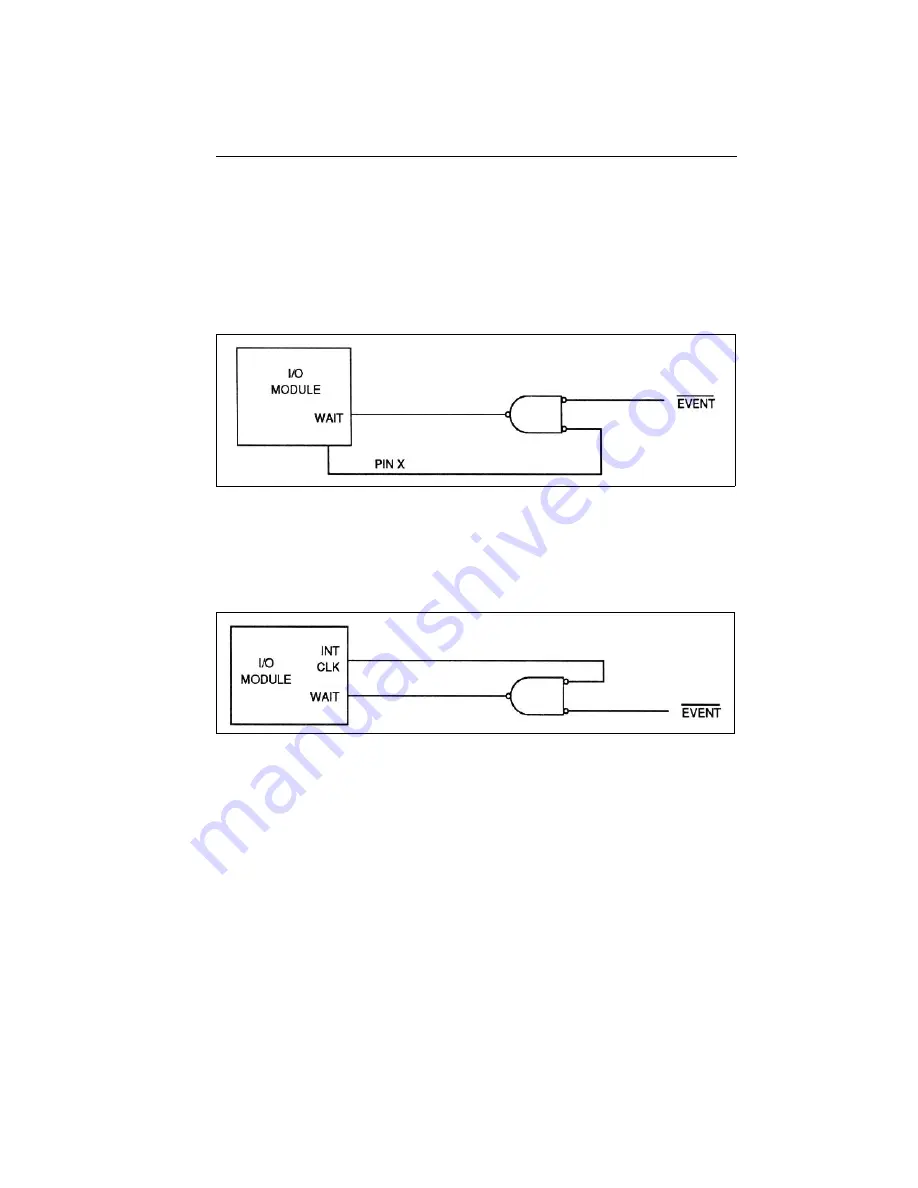

the line on the vector would provide the edge necessary to sat-

isfy the WAIT. If the controlling signal was not at the desired

level, vector driving would halt until the signal was set to the

correct level.

Figure 7-3. Using WAIT to Check for a Level (Method 1)

Another method would “AND” the controlling signal with the

Vector Output I/O Module INT CLK line (See Figure 7-4). This

method would provide an edge when the controlling signal was

satisfied.

Figure 7-4. Using WAIT to Check for a Level (Method 2)

TIMING SETS

7.18.

The Vector Output I/O Module does not require the use of timing

sets for most applications because of its pattern depth of 8192

vectors and loading time of 3 seconds for an 8K vector file.

However, to reduce programming time or the number of vector

files necessary, two Vector Output I/O Modules can be used to

provide timing sets.

One module would contain a vector file of the basic timing sets;

that is, the control signal vectors required to perform the read-

cycle, writecycle, or other cycles. The vector file would contain

a LOOP statement enclosing the cycle information set to the

Summary of Contents for 9100A Series

Page 6: ...vi ...

Page 8: ...viii ...

Page 10: ...x ...

Page 14: ...9100A 017 1 4 ...

Page 24: ...9100A 017 3 6 ...

Page 44: ...9100A 017 5 4 ...

Page 58: ...9100A 017 6 14 ...

Page 83: ...A 1 Appendix A New TL 1 Commands ...

Page 84: ...9100A 017 A 2 ...

Page 87: ...clockfreq 3 For More Information The Overview Of TL 1 section of the Programmer s Manual ...

Page 88: ...clockfreq 4 ...

Page 91: ...drivepoll 3 For More Information The Overview Of TL 1 section of the Programmer s Manual ...

Page 92: ...drivepoll 4 ...

Page 104: ...vectordrive 4 ...

Page 107: ...vectorload 3 For More Information The Overview Of TL 1 section of the Programmer s Manual ...

Page 108: ...vectorload 4 ...

Page 116: ...9100A 017 C 2 ...

Page 117: ...9100A 017 C 3 ...

Page 118: ...9100A 017 C 4 ...