C1 Controllers and Transmitters

Instruction Manual

September 2009

22

ARROW DOWN

−

RELIEVES

ON DECREASING OUTPUT

ARROW UP

−

RELIEVES

ON INCREASING OUTPUT

(OUTPUT AT SUPPLY

DURING SHUTDOWN)

(OUTPUT AT ZERO

DURING SHUTDOWN)

CONSTANT SUPPLY

PRESSURE

TO FINAL

CONTROL

ELEMENT

EXHAUST

RESET BELLOWS

RESTRICTION

RESET VALVE

GE23697

−

A

GE34724

−

A

E1063

SENSED

PRESSURE

PROPORTIONAL

BELLOWS

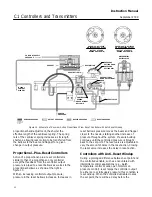

SENSED PRESSURE OUTPUT PRESSURE NOZZLE PRESSURE RESET PRESSURE

DIFFERENTIAL

RELIEF VALVE

CANTILEVER

SPRING

PRESSURE

SETTING DIAL

PROPORTIONAL

BAND ADJUSTMENT

KNOB

PRESSURE

SETTING KNOB

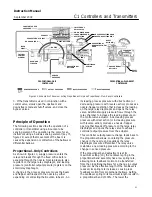

Figure 14. Schematic of Reverse

−

Acting Proportional

−

Plus

−

Reset Controller with Anti

−

Reset Windup

proportional band adjustment, the shorter the

effective length of the cantilever spring. The spring

rate of the cantilever spring increases as its length

shortens, allowing less motion to be transferred from

the bellows to the beam and flapper for a given

change in output pressure.

Proportional

−

Plus

−

Reset Controllers

Action of a proportional

−

plus

−

reset controller is

similar to that of a proportional

−

only controller

except that feedback from the controller output

pressure is piped to a reset bellows as well as to the

proportional bellows as shown at the right in

figure 13.

With an increasing controller output pressure,

pressure in the reset bellows increases. Increases in

reset bellows pressure moves the beam and flapper

closer to the nozzle, starting another increase of

pressure throughout the system. Pressure buildup

continues until the controlled pressure is brought

back to the set point. The reset valve is adjustable to

vary the amount of delay in the reset action. Closing

the reset valve increases the delay in reset action.

Controllers with Anti

−

Reset Windup

During a prolonged difference between set point and

the controlled variable, such as encountered with

intermittent control applications (e.g., batch

temperature control or wide open monitors on

pressure control), reset ramps the controller output

to either zero or full supply pressure; this condition is

reset windup. When the controlled variable crosses

the set point, there will be a delay before the