HEF7 series manual 30

16. Maintenance and cleaning

IMPORTANT

Request maintenance of your units by contacting:

https://

fisair.com/es/servicio/mantenimientos/ (application in Spanish)

https://

fisair.com/service/maintenance/ (application in English)

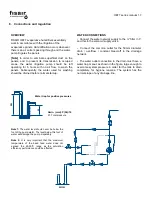

16.1.

Evaporative humidification: a natural method that does not carry bacteria.

The operational features of evaporative humidifiers are based on the natural effect of the water evaporation when an

air flow goes through/by a wet surface (is the same natural principle that occurs when water evaporates from waterfalls,

rivers, lakes, seas...).

Evaporation means that the water leaves the humidifier as pure vapour (gas). Minerals and eventual pollutants stay in

the water and can be eventually drained / eli

minated. With no droplets or aerosols carry over, the bacteria can’t be

transferred to the humidified air. It is important to use a droplet separator when it’s needed.

The evaporative humidifiers work with water temperatures below 24°C, very far from the optimal growth temperatures

of the bacteria present in the water, essentially Legionella pneumophila, with an optimum growth temperature of 37-

41ºC.

The water basin, manifold, irrigation system and the other components of the HEF2 series are specially designed for

there to be complete emptying by gravity, without the aid of mechanical elements. Based on the quality of treated air

and water supply, a cleaning and emptying inspection plan should be established.

16.2.

Cleaning

16.2.1.

General

An inspection, emptying and cleaning plan must be established for the HEF2 Series depending on the treated air and

feed water quality.

Evaporation humidifiers should be cleaned regularly to prevent contamination. All the component surfaces (panel, pipes

and especially the water deposit) must be disinfected with an appropriate solution.

A cleaning process must be carried out once a year to maximize the useful life of the Cassettes.

Special attention must be paid to the cleanliness of the piping system, especially where it diverts; and the cleaning

process must reach all parts of the system.

Summary of Contents for HEF7 Series

Page 2: ...HEF7 series manual 2...

Page 12: ...HEF7 series manual 12 5 Unit components 1 2 4 3 7 5 6...

Page 34: ...17 Machine conformity declaration...

Page 35: ...18 Cuasi machine conformity declaration...

Page 36: ...19 WARRANTY...

Page 37: ......