HEF2 Series MANUAL

91

14. WATER QUALITY, AIR QUALITY AND MAINTENANCE CONDITIONS

Water quality, air quality and maintenance conditions for the FISAIR high efficiency inorganic panel reaches

10,000 h in operation.

[Note]:

When the water to be supplied to the HEF2 requires treatment, this must be notified in advance

on the order, as different improvements in the HEF2 design are needed, depending on whether it is

softened or reverse osmosis water. Failure to provide this information could lead to different parts of

the equipment being damaged.

Water quality conditions: (for 10000 operating hours)

1. Conductivity: Conductivity: 60-350 µS/cm, inclusive. *)

2. Total hardness: (as CaCO3) Total hardness 20-100 mg/l, inclusive.

3. Ionic silica: (Si02) < 30 mg/l

4. Iron: (Fe) < 0.2 mg/l

5. Oils and fats: < 2 mg/l

6. Total dissolved solids: < 450 mg/l

7. pH: 6-8

8. Water quality standards described in table on pages 72-73.

*) maximum conditions 1000

μS / cm. The higher the conductivity, the shorter the hours of operation.

A table of required chloride (Cl) values for each type of water is attached. Damage caused by chlorine

corrosion is not covered by the FISAIR guarantee policy.

(*): When less than 60

μS/cm, Reverse Osmosis water

can be used between 30-60

μS/cm. For values below

30

μS/cm, contact FISAIR.

Air quality conditions:

Healthy air. Recommended pre-filter F7.

Maintenance conditions:

The cleaning protocol is not to extend the final life, but to maintain the expectation

of 10,000 h in operation. This must be done once a year.

Remark:

Humidifier cartridges are wearing parts and are not covered by the warranty.

Chlorides

Drinking

water

Softened water

Deionised

water

< 100 mg/l

< 70 mg/l

< 30 mg/l

Summary of Contents for HEF2 SERIES

Page 2: ...HEF2 Series MANUAL 2...

Page 13: ...HEF2 Series MANUAL 13 Machine type rating plate Partly completed machinery type rating plate...

Page 66: ...HEF2 Series MANUAL 66 Wiring Diagram connections Dimensions GDB13 1 GDB13 1...

Page 67: ...HEF2 Series MANUAL 67 Adjusting A B Auxiliary contacts...

Page 69: ...HEF2 Series MANUAL 69 Wiring Diagram connections Dimensions...

Page 70: ...HEF2 Series MANUAL 70 Manual positioning...

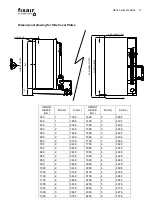

Page 76: ...HEF2 Series MANUAL 76 13 9 G Perimeter closures cover plates dimensional drawings...

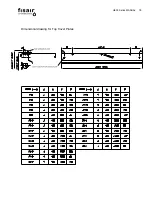

Page 78: ...HEF2 Series MANUAL 78 Dimensional drawing for Top Cover Plates...

Page 98: ...HEF2 Series MANUAL 98 H1 ON OFF or BUS...

Page 101: ...HEF2 Series MANUAL 101 1 Cassette ON 2 Cassettes ON 3 Cassettes ON Ideal Stage Control...

Page 102: ...HEF2 Series MANUAL 102 Control by stages or control ON OFF...

Page 103: ...HEF2 Series MANUAL 103 H1 ON OFF 0 10Vcc regulated or BUS...

Page 105: ...HEF2 Series MANUAL 105 Dew point control Dew point control...

Page 106: ...HEF2 Series MANUAL 106 H1 ON OFF or BUS...

Page 117: ...HEF2 Series MANUAL 117...

Page 120: ...HEF2 Series MANUAL 120 Remove the PP R D25 piping to the header PP R D25 pipe...

Page 121: ...HEF2 Series MANUAL 121...

Page 122: ...HEF2 Series MANUAL 122...

Page 123: ...HEF2 Series MANUAL 123...

Page 125: ...HEF2 Series MANUAL 125...

Page 126: ...HEF2 Series MANUAL 126 23 CLEANING THE INDIVIDUAL IRRIGATION SYSTEM...

Page 127: ...HEF2 Series MANUAL 127...

Page 128: ...HEF2 Series MANUAL 128 24 LIST OF SPARE PARTS...