9

E

N

15

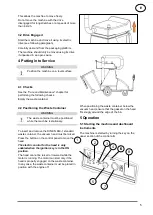

Pump

disconnected

During the initial

checks, the lifting

motor was found to

be disconnected,

check the wiring

and that there are

no interruptions

inside the motor.

6 Care and Maintenance

6.1 General Guidelines

Before cleaning and servicing the machine or

replacing components, turn it off and remove the

ignition key.

Disconnect the battery when working on the

electrical system.

Repairs should only be performed by authorised

service centres or by qualified personnel who are

familiar with all relevant current safety regulations.

6.2 Cleaning

WARNING

Do not clean the machine with a high-

pressure water spray (risk of short circuit

or other electrical failures).

DANGER

Wear a dust mask and safety goggles.

Remove the bonnet from the machine for internal

cleaning. Clean with a compressed air blower.

The outside of the machine should be cleaned with

a soft cloth and a mild detergent. Do not use

aggressive detergents.

6.3 Maintenance intervals

WARNING

The operating time meter indicates the

maintenance intervals.

The customer is responsible for the following

maintenance tasks:

Daily maintenance:

-

Check that all the controls are working.

-

Clean the gasket on the vacuum head.

-

Check the readability and presence of the

CE plate and the warning stickers on the

machine body.

-

Clean the filter

Weekly maintenance:

-

Check that the moving parts move freely.

-

Clean the machine.

-

Check that the vacuum fan rotates

properly.

-

Check the tightness of the fan hub.

-

Check the running of the electric motors,

ensuring that there is no hissing and/or

abnormal noises.

Maintenance every 100 working hours:

-

Check the battery acid level.

-

The machine chassis and welding must be

free from visible defects such as cracks,

deformations, incisions, corrosion, etc.

-

Make sure all the machine bolts are

securely tightened.

-

Check the condition and attachment of the

cables, connections and battery: electrical

cable jackets must be in good condition

and the terminals must be well tightened

and free from corrosion.

WARNING

All servicing and maintenance under the

customer

’s

responsibility must be

performed by a qualified technician.

The following maintenance operations are to be

carried out by the customer support service:

-

A first inspection after 20 hours.

-

Maintenance every 100 hours of operation.

For warranty purposes, all servicing and

maintenance during the warranty period should be

carried out by the

Ing. O. Fiorentini S.p.A.

authorised service.

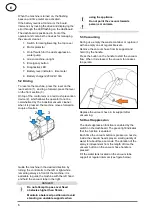

6.4 Battery maintenance

DANGER

Risk of explosion.

Never place tools or other objects on the

battery, the terminals or the battery

element connections. If they are

conductive, they could cause a short

circuit and trigger an electric arc.

Provide adequate ventilation during

charging to dispel possible explosive