6

E

N

When the machine is turned on, the flashing

beacon and time meter are activated.

If the battery level is at minimum, the board

intervenes by locking the drive and displaying the

error through the LED flashing on the dashboard.

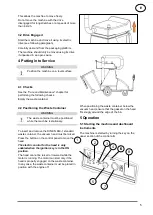

The dashboard is positioned in front of the

operator and contains the devices for managing

the vacuum cleaner:

1. Switch for raising/lowering the top cover

2. Motor protector

3. On/off switch for the dust suppression

water pump

4. Green machine-on light

5. Emergency button

6. Diagnostics LED

7. Battery level ind time meter

8. Battery charger 220V-24V 14A

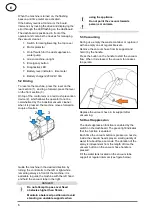

5.2 Driving

To reverse the machine, press the lever on the

rear section (1), and to go forward, press the lever

on the front section (3).

On top of the control arm is a red crush-prevention

device (2), which allows the operator to not be

overwhelmed by the industrial vacuum cleaner;

when it is pressed, the machine moves forward a

couple of metres.

Guide the machine in the desired direction by

turning the control arm to the left or right while

remaining always in front of the machine: it is

advisable to guide the machine with the left hand

and hold the vacuum tube in the right.

DANGER

Do not attempt to pass over fixed

obstacles higher than 50 mm.

Maintain a balanced position and avoid

standing on unstable supports when

using the appliance.

Do not point the vacuum towards

persons or animals.

5.3 Vacuuming

During use, empty the waste container or replace it

with an empty one at regular intervals.

Remove the vacuum hose from its support and

hold it by the handle.

Press the button on the handle to start the vacuum

flow. When it is released, the vacuum fan ceases

to operate.

Replace the vacuum hose in its support after

vacuuming.

5.4 Dust Suppression

The dust suppression function is enabled by the

switch on the dashboard. The green light indicates

that the function is enabled.

Each time the vacuum button is pressed, a nozzle

inside the vacuum head sprays a small quantity of

water for about three seconds. The duration of the

spray is independent from the length of time the

vacuum button on the vacuum hose handle is

pressed.

Fill the water tank located on the vacuum tube

support at regular intervals (see figure below).

1

2

3