Solenoid Coil

VACC-S13-11-K4-1-EX4A

II 2G Ex ia IIC T6, T5 Gb

II 2D Ex ia IIIC T80°C, T95°C IP64 Db

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Operating conditions EX

(Original instructions)

8070989

1702c

[8070991]

Solenoid coil VACC-S13-11-K4-1-EX4A

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

All available documents for the product

è

www.festo.com/pk

Note

Technical data for the product can have different values in other documents.

During operation in an explosive atmosphere, the technical data of this

document always has priority.

1

Certified solenoid coils

Voltage

Type

Part no.

14 … 32 V DC

VACC-S13-11-K4-1-EX4A

562896

Fig. 1

2

Function

When switching on the voltage, the solenoid is energised and the valve is actuated.

A built-in current pulse generator permits operation on low-power electric

networks.

3

Application

The solenoid coil is intended to be used to actuate Festo valves.

Operate the solenoid valve with compressed air only.

The device is not intended to be used with other fluids.

The solenoid coils can be used in combination with the specified solenoid valves

in zones 1 and 2 for potentially explosive gas atmospheres and in zones 21

and22 for potentially explosive dust atmospheres.

Note

Label X: special conditions

Only use specified solenoid valves.

The range of application is dependent on the ambient temperature.

The device must be connected to a certified Ex ia IIC or Ex ib IIC power circuit.

Protect the housing from mechanical impact > 4 years.

Protect the device from electrostatic discharge.

Protect the filling compound from mechanical impact energy.

4

Transport and storage

Observe the following storage conditions: short storage times in cool, dry,

shaded and corrosion-resistant locations.

5

Requirements for product use

Comply with all applicable national and international regulations.

Note

Installation and commissioning should only be carried out by qualified electrical

specialists.

6

Mounting

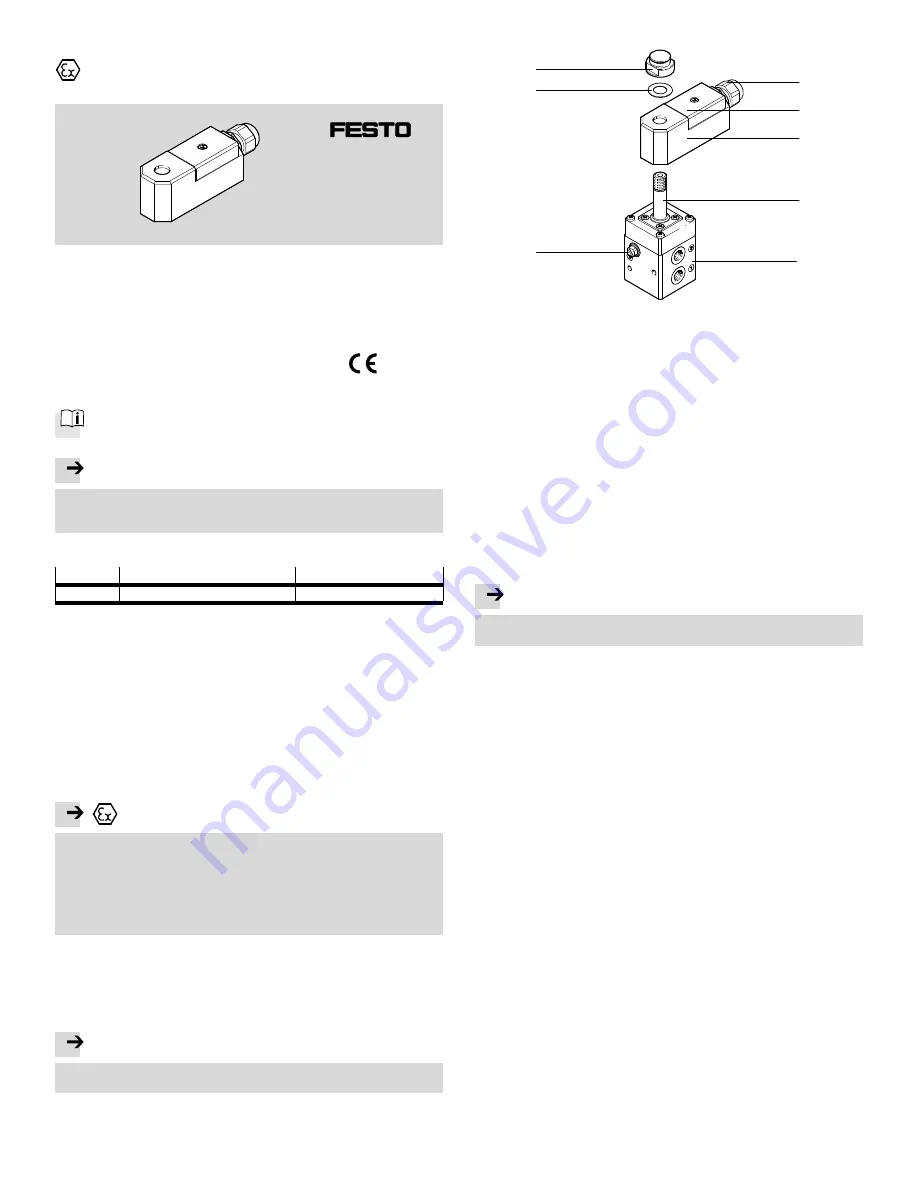

7

6

1

2

3

8

5

4

1

Port 12 (only for external pilot air

supply)

2

Ribbed disc

3

Vent screw/retaining nut

4

Cable fitting

(with cap nut)

5

Cover, terminal housing

6

Solenoid coil

7

Armature guide tube

8

Solenoid valve

Fig. 1

6.1 Mechanical

1. Tighten vent screw. Twisting the solenoid coil is no longer possible

(tightening torque 4…6 Nm).

2. Open cover of terminal housing.

3. Connect electrical cables to the terminals. Observe polarity (tightening

torque2…3 Nm).

4. Close the cover of the terminal housing

(tightening torque: 0.6…0.7 Nm).

5. With external pilot air supply, use connection 12.

6. Seal unused openings with blanking plugs or slot covers.

Note

The surface coating of the solenoid valves is electrically non-conductive.

Include the device in the system’s potential equalisation.

6.2 Pneumatic

1. Mount connecting cables and fittings properly. Before commissioning, remove

residue, such as chips, rust and water.

2. Depressurise the compressed air lines.

3. Use only fittings with cylindrical threaded lugs and sealing rings or cutting rings.

4. Do not use PTFE or hemp fibres on the threads.

5. Insert all sealing rings supplied with the NAMUR mounting kit between solenoid

valve and drive or mounting plate.

6. If port 1 with control signal < 2 bar, then supply auxiliary energy > 2 bar to

port 12.

7. Do not use anti-friction coating or lubricant.

8. The dew point of the compressed air must lie below the specified lowest operat

ing temperature of the system.

9. Use filter adapter NPFV-AF-G14-G14-MF or

NPFV-AF-G14-N14-MF.

10.Use exhaust protection VABD-D3-SN-G14.