40 / 48

Festo 7DGE_25-63_ZR_KFb_en

• Align the moment compensator towards the centre of the slide by turning

the two threaded pins. The distance between the moment compensator and

slide must be identical on both sides.

• Set the moment compensator by adjusting the threaded pins by feel so that

there is no perceptible longitudinal play between the slide and moment

compensator.

• Move the moment compensator and slide against each other during setting.

• Avoid bracing the moment compensator with the slide since this can have a

negative influence on the running characteristics of the guide.

4.6

Assembly and function check

After completing the assembly work on the toothed belt axis, the correct function must be checked by following the steps

below.

4.6.1

Buffer and belt assembly

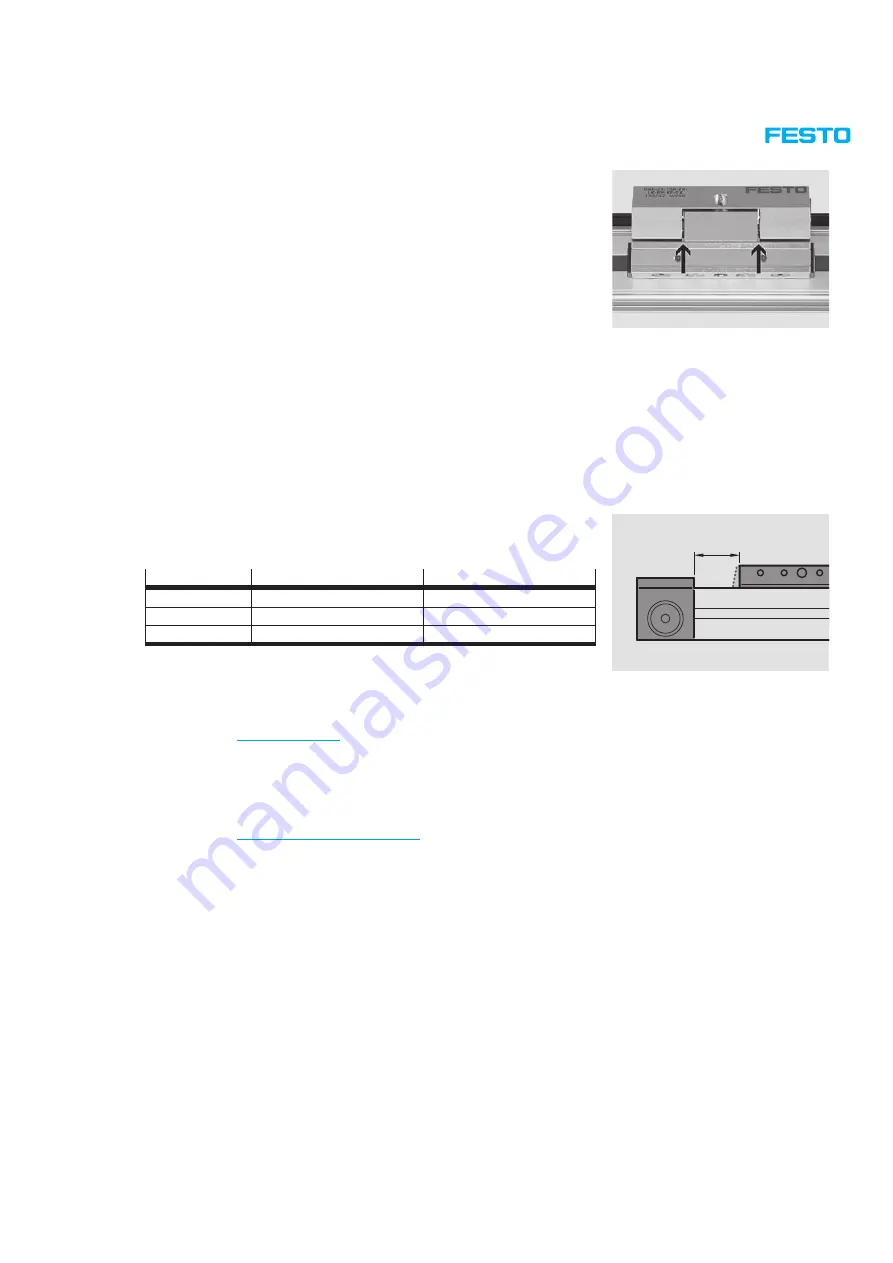

• Move the piston to each of the end positions of the toothed belt axis in turn

and then check the distance from the piston to the corresponding drive

cover (Y).

Type

Minimum distance Y

Maximum distance Y

DGE-25

19 mm

23 mm

DGE-40

30 mm

35 mm

DGE-63

44 mm

51 mm

If the distance (Y) is smaller than the specified minimum, the buffer may not

have been correctly assembled.

• Check the assembly of the buffer and fix the problem if necessary

If the distance (Y) is greater than the specified maximum, the toothed belt is too

short and the clamp piece cannot be screwed in far enough.

• Check the length of the toothed belt and replace it if necessary

4.4 “Replacing the toothed belt”

).

Y

4.6.2

Switching characteristics of the magnet

• Move the piston to the right-hand end of the toothed belt axis (recess in the

slot).

• Transverse the full slot using a suitable proximity sensor (type SME-8 or

SMT-8). The proximity sensor must respond in the area of the left-hand

piston side that is opposite the slot recess.

4.6.3

No-load torque

It must be possible to move the piston without much resistance or jerking when

idle, without a drive attached or load connected.

This check is based on the technician's instinct and experience. It is not possible

to specify precise test values.

Summary of Contents for DGE-25 ZR RF Series

Page 47: ......

Page 48: ......

Page 49: ...Operating instructions en Toothed belt pretension test equipment 7Tension01_TBb_en...