5. Supply compressed air.

Ä

Process valve opens. Pistons move to the outer end position against the

threaded rod.

6. Check position of the process valve.

To modify the swivel angle, repeat steps 3 … 6.

7. Tighten the lock nut with sealing ring on the threaded rod.

–

Tightening torque: 5 Nm

9.4

Manual override

Requirements

–

Semi-rotary drive is not pressurised.

Actuating the drive using the manual override

1. Unhook retaining spring.

2. Remove protective cover from display.

3. Open/close valve using handwheel:

–

To open DAPS-...-R-... (double-acting): rotate handwheel anti-clockwise

until the indicator has moved inward.

–

To open DAPS-...-RS-... (single-acting): rotate handwheel anti-clockwise

until the indicator has moved outward.

–

To close DAPS-...-R-... (double-acting): rotate handwheel clockwise until

the indicator has moved outward.

–

To close DAPS-...-RS-... (single-acting): rotate handwheel clockwise until

the indicator has moved inward.

4. Rotate the handwheel back until the indicator is in the mid-position (neutral

position)

è

5. Fit the protective cover.

6. Attach the retaining spring.

Ä

The drive can once more be actuated pneumatically.

10

Maintenance

When used as intended, the product is maintenance-free.

11

Malfunctions

NOTICE!

Repairs to the product are not permissible. In the event of malfunctions or failure:

Replace the product and let Festo know about the failure. Return defective

products to Festo.

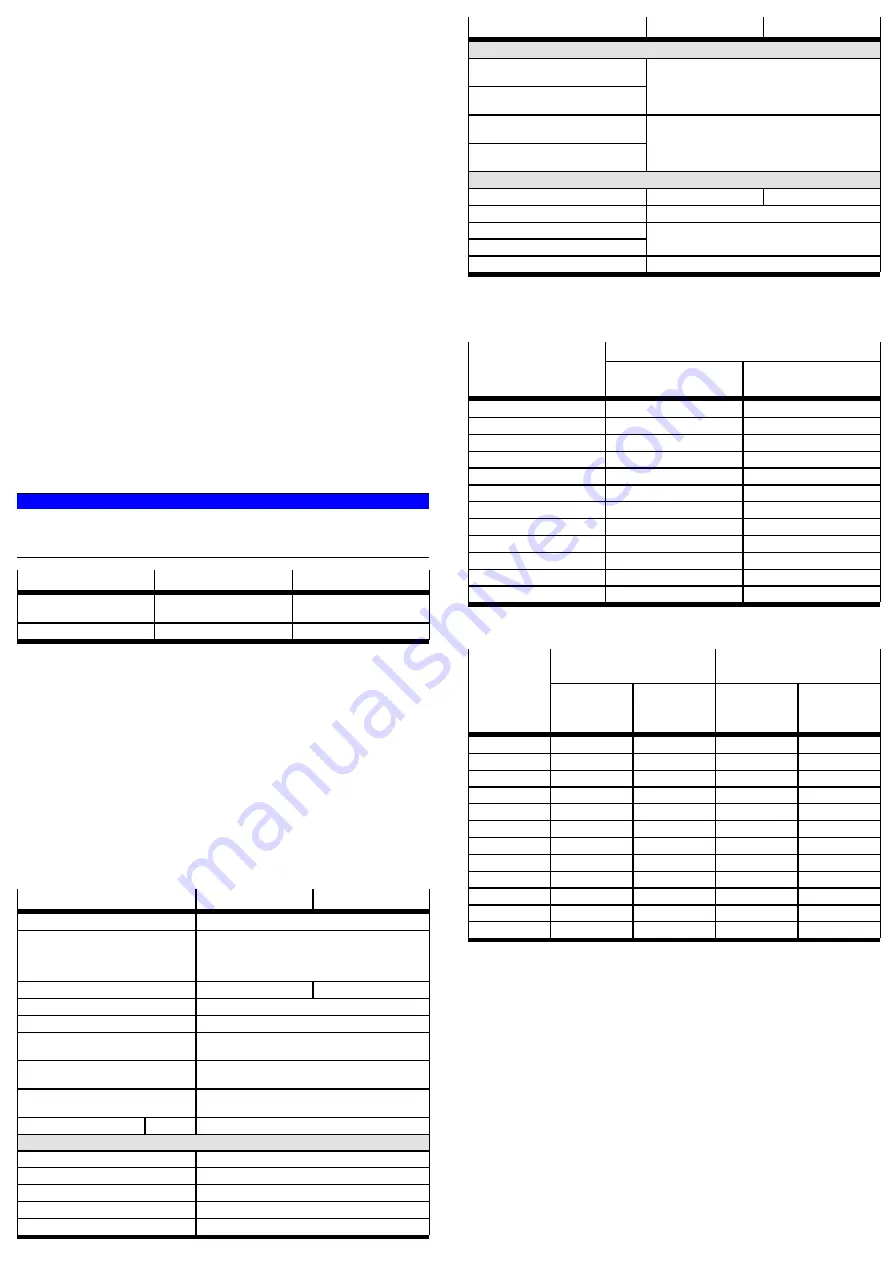

Fault description

Cause

Remedy

Drive does not move in the

desired direction.

Compressed air connections are

connected incorrectly.

Correct the tubing connection.

Leakage

No seal in the slot

Insert seal in the slot.

Tab. 3

12

Dismounting

1. Switch off the power supply.

2. Loosen the pneumatic connections.

3. Remove external attachments.

4. Undo the retaining screws of the drive at the process valve and remove the

drive.

13

Disposal

•

Observe the local regulations for environmentally friendly disposal.

•

Dispose of the product in an environmentally friendly manner. When doing

this, also take residual media into account (recycling of hazardous waste

where appropriate).

14

technical data

DAPS-...-MW

DAPS-...-MW-T6

Operating medium

Compressed air to ISO 8573-1:2010 [7:4:4]

Note on the operating medium

Lubricated operation possible (in which case lubricated

operation will always be required)

Ester oil

<

0.1 mg/m

#

, complies with

ISO 8573:2010 class [-:-:2]

Ambient temperature

[°C]

–20 … +80

–50 … +60

swivel angle

[°]

92

Mounting position

Any

Valve connection conforms to

standard

VDI/VDE 3845 (NAMUR)

Standards-based connection

to fitting

ISO 5211

CE marking (declaration of conformity

è

www.festo.com/sp)

To EU Explosion Protection Directive (ATEX)

Nominal operating pressure

[bar]

5.6

Operating pressure

1)2)

DAPS-...-R-...

[bar]

1 … 8.4

DAPS-...-RS1-...

[bar]

2.8 … 8.4

DAPS-...-RS2-...

[bar]

3.5 … 8.4

DAPS-...-RS3-...

[bar]

3.5 … 8.4

DAPS-...-RS4-...

[bar]

5.6 … 8.4

DAPS-...-MW

DAPS-...-MW-T6

Pneumatic connection

DAPS-0053-...-RS-... to

DAPS-0180-...-RS-...

DAPS-0106-...-R-... to

DAPS-0360-...-R-...

G

x

DAPS-0240-...-RS-... to

DAPS-0960-...-RS-...

DAPS-0480-...-R-... to

DAPS-1920-...-R-...

G

¼

Materials

Seals

NBR, FPM, HNBR

FVMQ, PTFE reinforced

Shaft

High-alloy steel (1.4305)

Cover

Housing

Wrought aluminium alloy

Screws

High-alloy steel

1) The min. operating pressure varies for single-acting semi-rotary drives depending on the number of

springs.

2) Exceptions for devices with special identification

Tab. 4

Switching time [s] per cycle

1)

Type

DAPS-...-RS-...-MW-...

(single-acting)

DAPS-...-R-...-MW-...

(double-acting)

DAPS-0053-...

0.89

–

DAPS-0090-...

1.3

–

DAPS-0106-...

–

0.41

DAPS-0120-...

1.71

–

DAPS-0180-...

2.70

0.63

DAPS-0240-...

2.2

0.81

DAPS-0360-...

3.6

1.18

DAPS-0480-...

3.8

1.54

DAPS-0720-...

4.7

2.1

DAPS-0960-...

6.3

3.1

DAPS-1440-...

–

4.7

DAPS-1920-...

–

6.3

1) Average values under no-load conditions

Tab. 5

DAPS-...-RS-...-MW-... (single-

acting)

DAPS-...-R-...-MW-... (double-

acting)

Type

Required

manual force

[N]

1)

Number of

revolutions

2)

Required hand

wheel [N]

1)

Number of

revolutions

2)

DAPS-0053-...

13.9

13

–

–

DAPS-0090-...

22.2

16

–

–

DAPS-0106-...

–

–

13.9

13

DAPS-0120-...

27.3

18

–

–

DAPS-0180-...

33.7

15

22.2

16

DAPS-0240-...

41.7

16

27.3

18

DAPS-0360-...

54.4

19

33.7

15

DAPS-0480-...

64.3

20

41.7

16

DAPS-0720-...

68.5

25

54.4

19

DAPS-0960-...

81.3

26

64.3

20

DAPS-1440-...

–

–

68.5

25

DAPS-1920-...

–

–

81.3

26

1) Required force to override the nominal torque when actuating the hand wheel

2) Number of required revolutions for opening and closing using the hand wheel starting from the neutral

position

Tab. 6