1

2

3

4

5

6

7

8

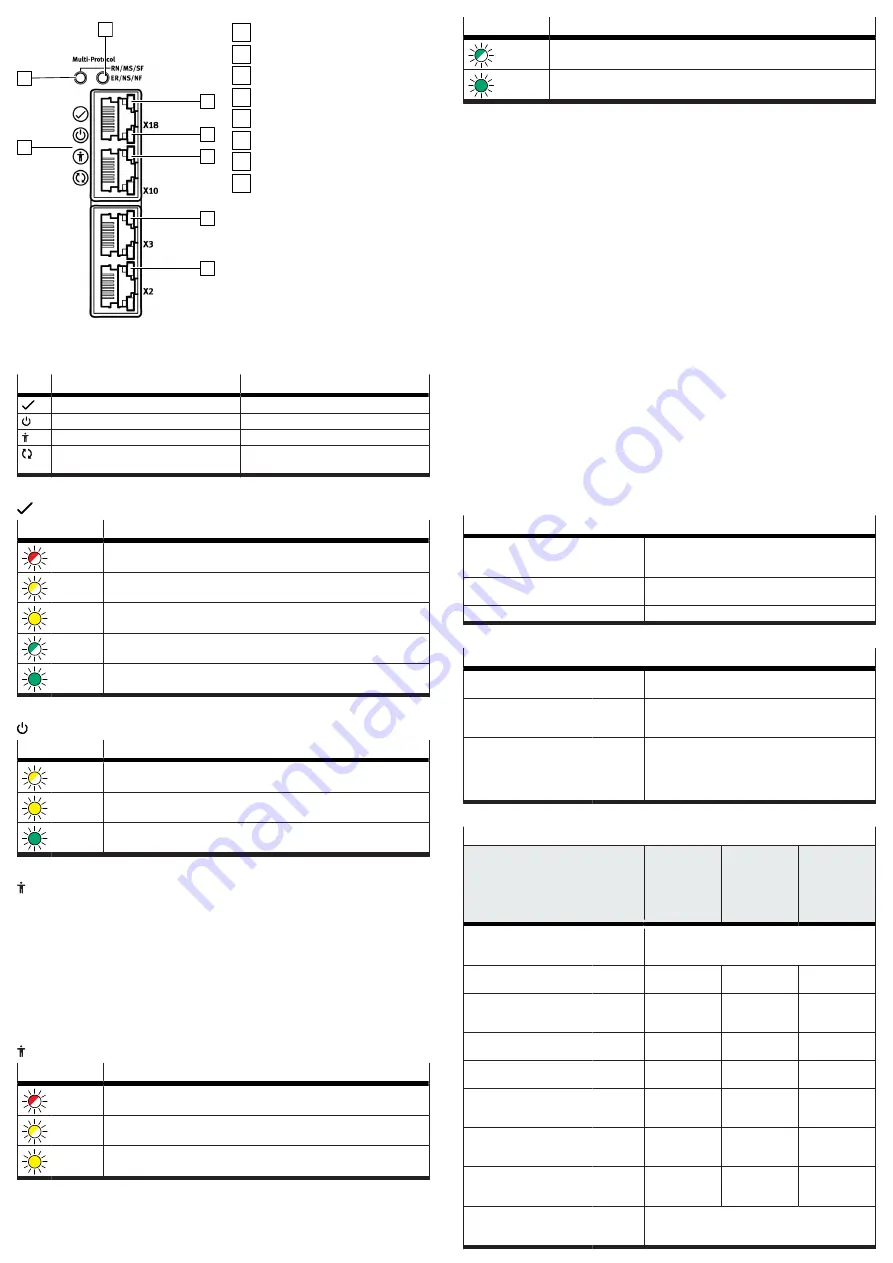

Fig. 12: LEDs on the front

1

Device status (4 LEDs)

2

RN/MS/SF (example CMMT-AS-...-MP)

3

ER/NS/NF (example CMMT-AS-...-MP)

4

Ethernet interface activated [X18]

5

Communication activity [X18]

6

Sync interface activated [X10]

7

Encoder status, encoder interface [X3]

8

Encoder status, encoder interface [X2]

11.1.1

Device status displays

LED

Identifier

Brief description

Status LED

Indicates the general device status

Power LED

Indicates the status of the power supply

Safety LED

Indicates the status of the safety equipment

Application status LED

Indicates the identification sequence and is

reserved for future extensions

Tab. 46: Device status LEDs (status, power, safety and application status LEDs)

Status LED, display of the device status

LED

Meaning

flashes

red

An error is present.

flashes

yellow

A warning is present, or the servo drive is currently performing a firmware

update.

yellow

light

The servo drive is in the initialisation phase.

flashes

green

The servo drive is ready, and the power stage is switched off (Ready).

green

light

The power stage and the closed-loop controller are enabled.

Tab. 47: Status LED

Power LED, status of the power supply

LED

Meaning

flashes

yellow

The logic voltage and AC supply are present. The intermediate circuit is being

charged.

yellow

light

The logic voltage supply is present, but the AC supply is lacking.

green

light

The logic voltage supply is present, and the intermediate circuit is charged.

Tab. 48: Power LED

Safety LED, status of the safety equipment

Malfunctions of the safety sub-functions are detected and displayed in the func-

tional device. The following are detected:

–

Safety sub-functions requested via 1 channel (discrepancy monitoring)

–

Internal device errors that lead to pulse monitoring not being switched off or

only switched off on one channel

–

Errors in the brake outputs or the external wiring that result in voltage being

present on the brake output even though the safety sub-function SBC has been

requested

Malfunctions are externally reported by the functional part, including via the

additional communication interfaces (bus, commissioning software).

Safety LED, status of the safety engineering

LED

Meaning

flashes

red

Error in the safety part or a safety condition has been violated.

flashes

yellow

The safety sub-function has been requested but is not yet active.

yellow

light

The safety sub-function has been requested and is active.

LED

Meaning

flashes

green

Power stage, brake outputs and safety diagnostic outputs are blocked (safety

parameterisation is running).

green

light

Ready, no safety sub-function has been requested.

Tab. 49: Safety LED

11.2

Repair

Repair or maintenance of the product is not permissible. If necessary, replace the

complete product.

1. If there is an internal defect: Always replace the product.

2. Send the defective product unchanged, together with a description of the

error and application, back to Festo.

3. Check with your regional Festo contact person to clarify the conditions for the

return shipment.

12

Disassembly

Disassemble in reverse order of installation.

Before disassembly

1. Switch off the power supply at the main switch.

2. Secure the system against accidental reactivation.

3. Wait at least 5 minutes until the intermediate circuit has discharged.

4. Let the device cool down to room temperature.

5. Before touching the power connections [X6A], [X9A], [X9B], check to ensure

they are free of voltage.

6. Disconnect all electrical cables.

To dismount the device

•

Loosen retaining screws (2x) and remove the device from the mounting sur-

face.

13

Technical data

13.1

Technical data, safety engineering

Approval information, safety engineering

Type test

The functional safety engineering of the product has

been certified by an independent testing body, see EC-

type examination certificate

Certificate issuing authority

TÜV Rheinland, Certification Body of Machinery, NB

0035

Certificate no.

01/205/5640.00/18

Tab. 50: Approval information, safety engineering

General safety reference data

Request rate in accordance

with EN 61508

High request rate

Reaction time when the

safety sub-function is

requested

[ms]

<

10 (applies to STO and SBC)

Error reaction time (how long

it takes for the diagnostic

output status to become cor-

rect once the safety sub-func-

tion has been requested)

[ms]

<

20 (applies for STA and SBA)

Tab. 51: Safety reference data and safety specifications

Safety reference data for the safety sub-function STO

Circuitry

Without high

test pulses,

without or

with STA

evaluation

With high

test pulses

and with STA

evaluation

1)

With high

test pulses

and without

STA evalua-

tion

Safety sub-function

in accordance with

EN 61800-5-2

Safe torque off (STO)

Safety integrity level in

accordance with EN 61508

SIL 3

SIL 3

SIL 2

SIL claim limit for a sub-

system in accordance with

EN 62061

SIL CL 3

SIL CL 3

SIL CL 2

Category in accordance with

EN ISO 13849-1

Cat. 4

Cat. 4

Cat. 3

Performance level in accord-

ance with EN ISO 13849-1

PL e

PL e

PL d

Probability of dangerous

failure per hour in accord-

ance with EN 61508, PFH

[1/h]

3.70 x 10

–11

9.40 x 10

–11

5.90 x 10

–10

Mean time to dangerous

failure in accordance with

EN ISO 13849-1, MTTF

d

[a]

2400

1960

1960

Average diagnostic cov-

erage in accordance with

EN ISO 13849-1, DC

AVG

[%]

97

95

75

Operating life (mission

time) in accordance with

EN ISO 13849-1, T

M

[a]

20