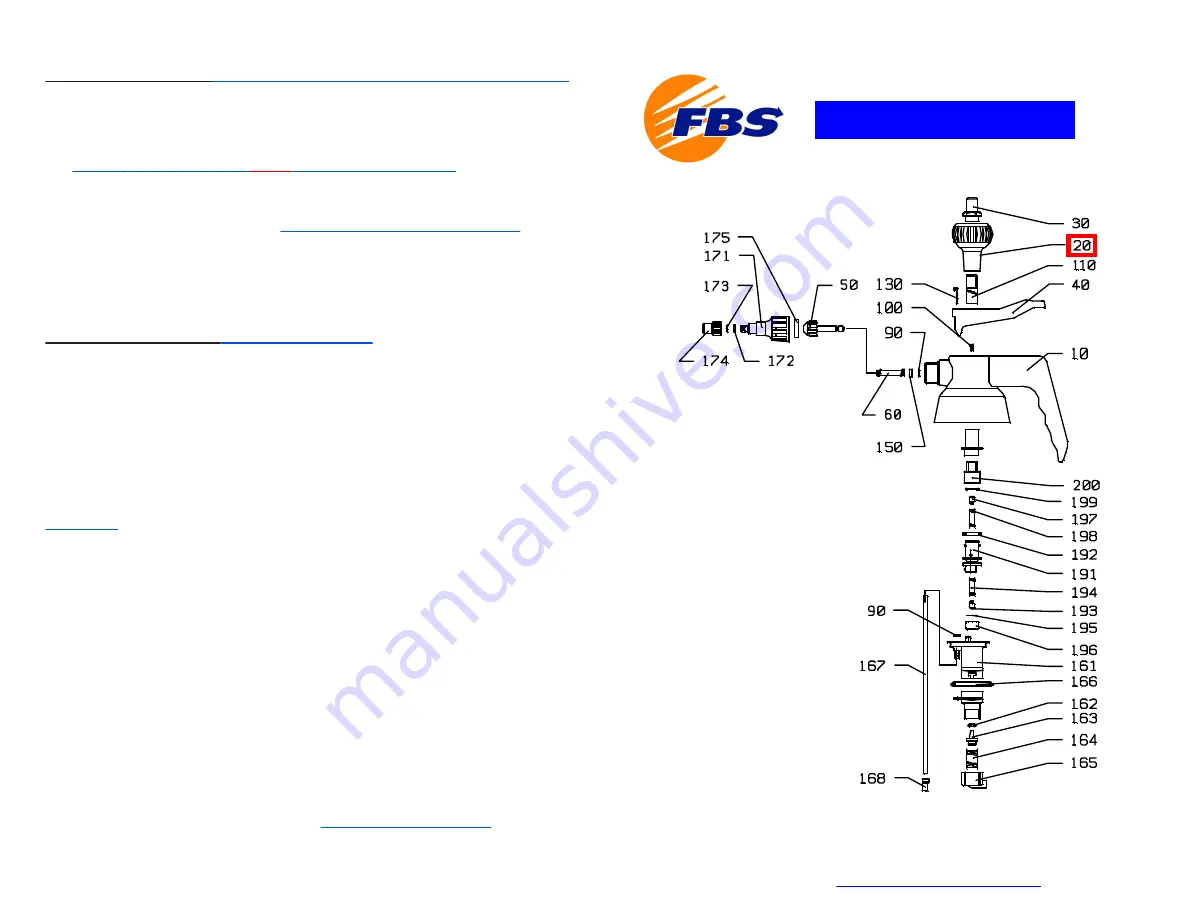

200

Upper ball seat cap

199

O-Ring ø 11.0 x 1.5

198

Excess pressure spring

197

Plastic ball

196

Lower ball seat cap

195

O-Ring ø 8.0 x 1

194

Excess pressure spring

193

Plastic ball

192

O-Ring ø 13.1 x 3.5

191

Bell-shaped valve

175

Nozzle head seal

174

Nozzle nut

173

Brass nozzle ø 0.8 mm

172

O-Ring øn 5.0 x 1.5

171

Swirl piece

168

Filtre

167

Suction Tube

166

O-Ring ø 36.0 x 4.0

165

Screw Cap

164

Valve Spring

163

Valve Plunger

162

O-Ring ø 3.0 x 2.7

161

Pump Cylinder

150

Retaining Disk

130

Clip

120

Pump Handle Guide

110

Pump Handle VARIO

100

Screw

90

O-Ring ø 5.0 x 1.5

60

Spring

50

Swirl Cone

40

Trigger for Safety Catch

30

Compressed air connection sleeve

20

Top of the pump handle

10

Sprayer cup

Manual

VARIO Compressed Air Sprayer

50401 EPDM-FPV/FPE Model

Instructions for Use –

Compressed Air Operation (1/4” connector)

•

Fill the bottle up to the “Max” indicator.

•

Insert pump assembly into the bottle, and screw-on very tightly, so the

seals can maintain sufficient pressure.

•

Extend the pump plunger (

no. 20

) to its maximum length.

•

Attach the compressed air connection sleeve (no. 30, 1/4” connector) on to

the compressed air coupling for approximately 3 – 5 seconds, in order to

build up pressure in the bottle.

Maximum pressure 3 bars * 43.5 psi

•

Slowly turn the nozzle to adjust spray pattern from fine mist to jet.

•

If liquid drops out of the nozzle on completion of spraying, spray for

approx. 2 – 3 seconds to release the trapped compressed air.

Instructions for Use –

Manual Operation

•

Fill the bottle up to the “Max” indicator..

•

Insert pump assembly into the bottle, and screw-on very tightly, so the

seals can maintain suffici ent pressure.

•

Extend pump plunger

(

no. 20

)

and stroke 20 – 30 times.

•

Slowly turn the nozzle to adjust spray pattern from fine mist to jet.

•

Always release pressure in the unit before storage.

Warranty

Sprayers carry a limited Warranty, which is limited to replacement of defective

part(s) only. Damage attributable to improper use, faulty maintenance, the effects

of chemicals or normal wear and tear (Seals/o-rings) is excluded from the

Warranty.

Effect of Acetone on plastic parts in the sprayers is also excluded form the

Warranty.

If defective, the sprayer(s) should be returned to FBS for examination with

transportation prepaid. If defects are covered by the Warranty, the least expen-

sive inbound/outbound charges will be borne by FBS/Manufacturer.

All returned and repairable sprayers not covered by the Warranty will be

repaired/reconditioned according to the repair fee/schedule, and charges borne

by the customer.

For more information visit our web site at

and check

chemical compatibility of EPDM.

Manufactured in Germany

FBS Distribution Co., Inc.