9

[Note]:

①

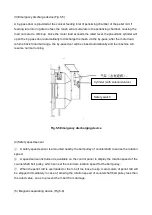

The installation diagram has only listed one specific condiitoner as an example.The

installatio diagram for other conditioners shall be provided according to the contract.

②

Remove the supporting rack of rotor after installation of the principal machine.The rack

is set to eliminate the vibration of rotor during transportation.

4.2.2Connection of compressed air pipeline

(1)Correct use of filtered compressed air is significant for normal operation of the pellet mill.

(2)Connection of compressed air pipelines for the cylinder:

The pressure of compressed air required for the cylinder of the discharging device outside the

machine at the inlet gate of the pellet mill shall be greater than 0.3Mpa.

(3)The connection of compressed air pipelines for the pneumatic lubrication device:

Compressed air with a pressure above 0.4Mpa should be provided.

4.2.3Installation of steam pipeline

Refer to Section 3.3.3 Steam system for the installation process flow of steam pipelines and type

selection of pipe fittings.

Note:

(1)The steam pipeline should be installed by professional installation company according to local

laws and regulations.

(2)Abide by rules and regulations on steam quality and capacity in this Operation Manual.

(3) Insulate all the steam pipelines.

(4) Abide by rules and regulations for steam quality and capacity. Cover the steam inlet and

discharge with thermal insulating layer.

(5) Rinse the pipes to remove all dirt.Check the steam pipes whether they are sealed or not after

installation.

(6)ALL the filters must be cleaned out after the first use.

4.2.4 Electric connection

(1) Connect the principal machine, control system and electric panelsto power supply according to

local rules and regulations on electric connection.