INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

29

Final Checks

Note:

The clock must be set before the ovens will work. See

‘

The Clock

’ section for instructions on setting the time of day.

Hotplate Check

Check each burner in turn. There is a Flame Supervision

Device (FSD) that stops the flow of gas to the burner if the

flame goes out. For each burner, turn the control knob to the

solid flame symbol. Press in the control knob. This lets gas

through to the burner. Keep holding the knob pressed in and

press the igniter button or light with a match. Keep holding

the control knob pressed in for about 10 seconds.

If, when you let go of the control knob the burner goes out,

the safety device has not held in. Wait one minute then try

again this time holding the control pressed in for slightly

longer.

Grill Check

Open the grill compartment door. Turn on the grill control

and check that the grill heats up.

Oven Check

Turn on the oven and check that it starts to heat up. Check

that the oven lights are working.

Note:

The oven light bulb is not included in the guarantee.

Turn off the oven.

Final Fitting

Fitting the Plinth

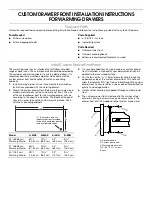

Remove the 4 screws for the plinth mounts along the front

bottom edge of the cooker

(Fig.7-15)

. Fasten the plinth using

these screws (alternative colour screws can be found in the

loose parts pack).

Fitting the Splashback

Position the splashback on the rear of the hotplate and secure

with the screws supplied.

Customer Care

Installer:

Please complete your details in this guide, inform

the user how to operate the cooker and hand over the

instructions.

Thank you.

ArtNo.281-0026 - Front plinth

Fig.7-15

Summary of Contents for Elan 110 Dual Fuel

Page 1: ...Elan 110 Dual Fuel Australia USER GUIDE INSTALLATION INSTRUCTIONS ...

Page 2: ......

Page 4: ...ii ...