Page

Chapter: 4

Section:

DRO MODE OF OPERATION

6

N

7

6

5

I

K

4

3

2

1

A

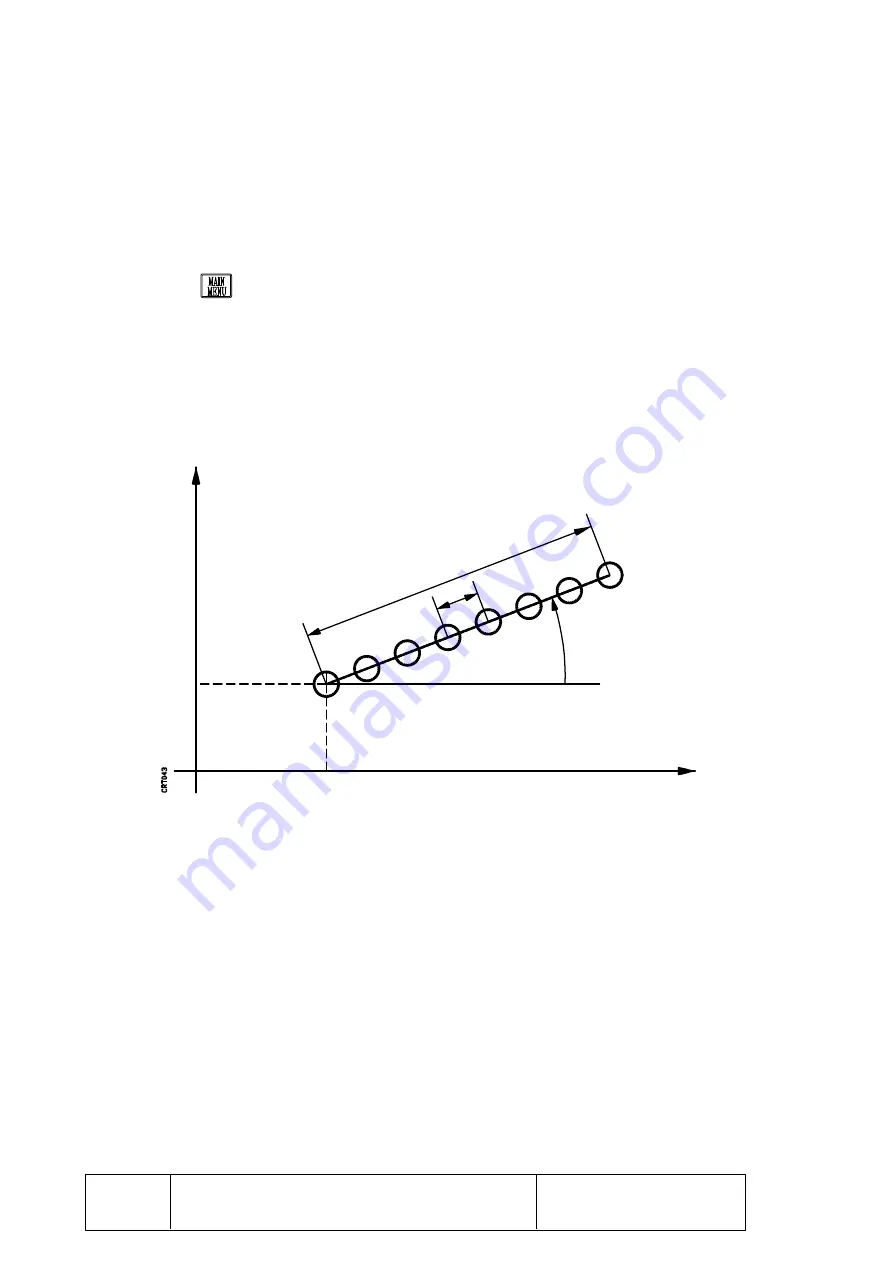

4.1.2 DRILLING IN A LINEAR PATTERN

The linear drilling operation can be carried out either in absolute or incremental

modes.

Follow these steps to select this function:

*

Press

and select “SPECIAL FUNCTIONS”.

*

Select “DRILLING IN LINE”.

Indicate the two axes which form the main axes where the drilling will be carried out.

The following parameters must be defined in order to perform a linear drilling

operation:

1st and 2nd axes Define the coordinates of the first drilling point in ABS or INC.

If none of these two parameters are defined, the DRO will take a value of 0.

A

Defines the angle formed by the drilling path (line) and the abscissa axis

(horizontal). It is given in degrees and if no value is programmed, the DRO will

take a value of 0.

I

Defines the distance between holes.

If a value is assigned to this parameter, no value must be assigned to “K”.

1st Axis

2nd Axis

DRILLING IN A LINEAR

PATTERN

Summary of Contents for VNP400

Page 1: ...FAGOR VNP400 Ref 9506 in...