·288·

Programming manual

CNC 8055

CNC 8055i

12.

PROBING

·M· & ·EN· M

ODELS

S

OFT

: V02.2

X

PROBE 1. Too

l leng

th

cal

ibratin

g ca

nne

d cycl

e

12.3

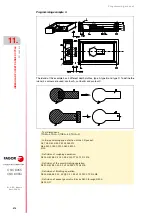

PROBE 1. Tool length calibrating canned cycle

This is used to calibrate the length and radius of the selected tool. The following operations are

possible with this cycle.

• Calibrate the length of a tool.

• Calibrate the radius of a tool.

• To calibrate the tool radius and length.

• Measure the length wear of a tool.

• Measure the radius wear of a tool.

• Measure the radius wear and length wear of a tool.

To perform this cycle it is necessary to have a table-top probe, installed in a fixed position on the

machine and with its faces parallel to axes X, Y, Z. Its position will be indicated in absolute

coordinates with respect to machine zero by means of the general machine parameters:

PRBXMIN

Indicates the minimum coordinate occupied by the probe along the X axis.

PRBXMAX

Indicates the maximum coordinate occupied by the probe along the X axis.

PRBYMIN

Indicates the minimum coordinate occupied by the probe along the Y axis.

PRBYMAX

Indicates the maximum coordinate occupied by the probe along the Y axis.

PRBZMIN

Indicates the minimum coordinate occupied by the probe along the Z axis.

PRBZMAX

Indicates the maximum coordinate occupied by the probe along the Z axis.

If it is the first time that the tool length has been calibrated, it is advisable to include an approximate

value of its length (L) in the tool offset table.

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......