- 43 -

k)

Recheck that the 3/4” blocks fit just snugly under the brackets and that the

tension on all the chains are approximately equal. Make sure all chain

attachment bolts are tight. Reposition anti-scalp rollers and tighten securely.

FIG. 11

SWIVEL ADJUSTMENT

SPRING COMPRESSION ADJUSTMENT

l)

Raise deck lift lever to the 5” cutting height position See Fig 9. Adjust spring

compression until proper distance is obtained between the two large washers

(See Fig 11). Adjustment is made by turning the nut at the front of each

spring (clockwise will shorten the spring, counter-clockwise will lengthen the

spring). Lock in position with jam nuts.

NOTE: When above adjustments have been made, the front of the

deck will be slightly lower than the rear of the deck.

5.2.3

Pump Drive Belt Tension.

Self-tensioning - No adjustment necessary.

5.2.4

Mule Drive Belt Tension Adjustment.

Self-tensioning idler, adjust as follows:

a)

Stop engine and remove key.

b)

Check to make sure the center of the bolt head in the center of the spring

loaded pulley, on left side engine deck support, is positioned between the

centers of the two alignment holes in the left support plate (See Fig 12). It is

necessary to adjust the belt tension when the center of the bolt head is at or

below the center of the bottom alignment hole.

c)

When adjustment is necessary, loosen the idler pulley on the right-hand

side so it can move up and down in the slot.

Place a wrench on the 3/8” nut in the center of the spring loaded pulley and

apply upward pressure to relieve tension on the spring (a 1/2” drive breaker

bar and 9/16 socket works best).

Reposition the adjusting pulley to the bottom of the slot.

NOTE: When installing a new belt, it is necessary to reposition the right

adjusting pulley upward in the slot in order to position the center of the

spring loaded pulley between the alignment holes.

FIG. 12

MULE DRIVE BELT ADJUSTMENT

Summary of Contents for Laser Z LZ18KC523

Page 1: ......

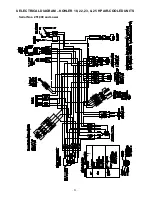

Page 57: ... 52 8 ELECTRICAL DIAGRAM KOHLER 18 22 23 25 HP AIR COOLED UNITS Serial Nos 251 999 and Lower ...

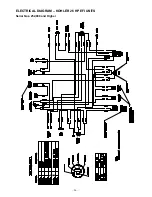

Page 58: ... 53 ELECTRICAL DIAGRAM KOHLER 23 25 HP AIR COOLED UNITS Serial Nos 252 000 and Higher ...

Page 59: ... 54 ELECTRICAL DIAGRAM 22 23 HP KAWASAKI LIQUID COOLED UNITS ...

Page 60: ... 55 ELECTRICAL DIAGRAM KOHLER 26 HP EFI UNITS Serial Nos 251 999 and Lower ...

Page 61: ... 56 ELECTRICAL DIAGRAM KOHLER 26 HP EFI UNITS Serial Nos 252 000 and Higher ...

Page 62: ... 57 ELECTRICAL DIAGRAM 23 HP KAWASAKI AIR COOLED ...

Page 63: ... 58 ELECTRICAL DIAGRAM 27 HP KAWASAKI LIQUID COOLED ...

Page 64: ... 59 9 HYDRAULIC DIAGRAM ...

Page 67: ... 62 NOTES ...

Page 68: ... 63 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 69: ... 64 ...