Machine control – Operating elements

Machine display

22

099-00T500-EW501

2.9.2022

Item Symbol Description

0

20

I

2

Signal light for secondary current

4.2 Machine display

The following welding parameters can be displayed before (nominal values), during (actual values) or af-

ter welding (hold values). The display of the hold values is indicated by the signal light :

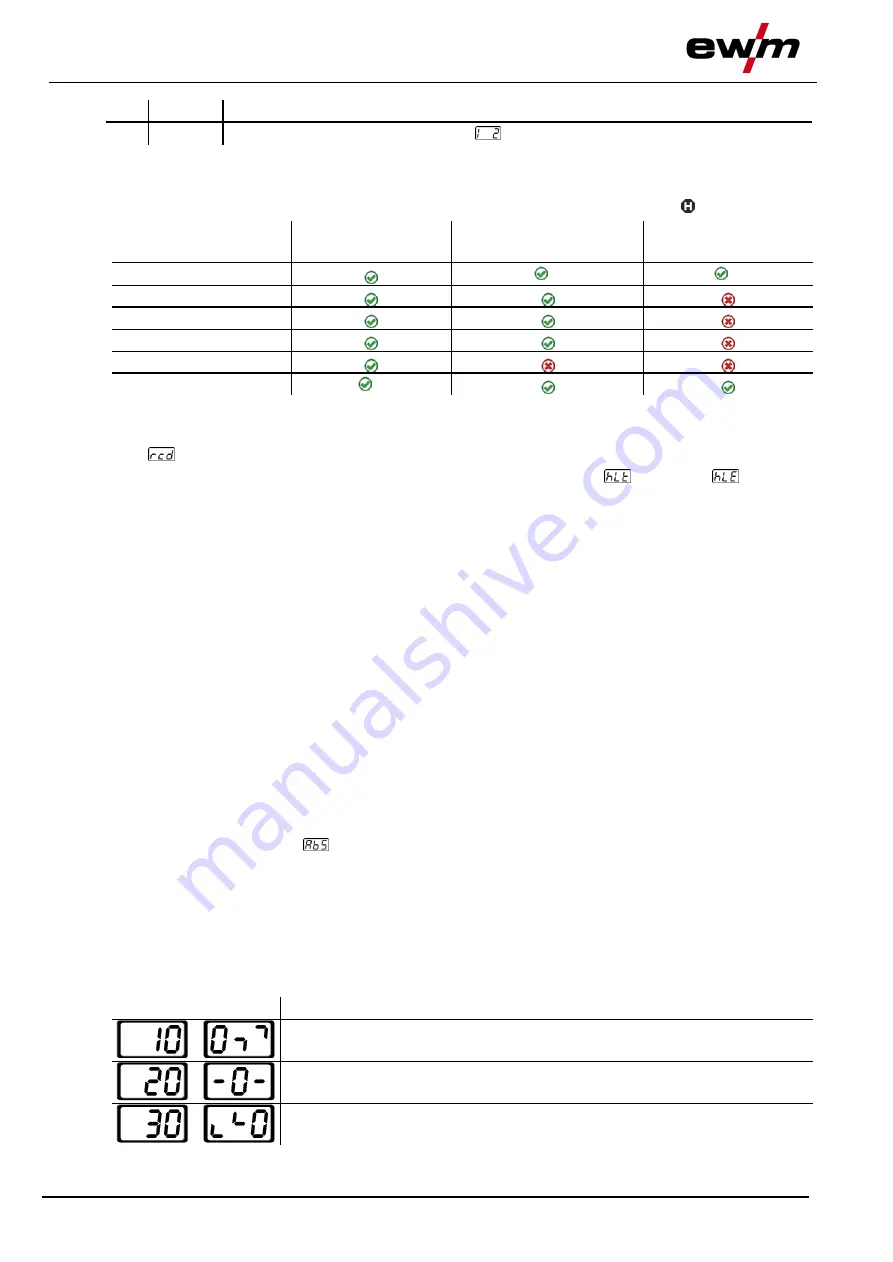

Parameter

Before welding

(nominal values)

During welding

(actual values)

After welding

(hold values)

Welding current

[2]

[3]

Parameter times

Parameter currents

Frequency, balance

JOB number

Welding voltage

[1]

[1]

not for MMA welding

[2]

The actual value display of the welding current for MMA can be switched on or off with the parame-

ter

.

[3]

The behaviour of the hold value display can be set with the parameters

for TIG and

for MMA.

The settings are made in the machine configuration menu

> see 5.11 chapter

.

The parameters that can be set in the machine control function sequence are dependent on the welding

task selected. This means that if no pulse variant was selected, for example, no pulse parameters will be

available to set in the function sequence.

4.3 Operating the machine control

4.3.1 Main screen

After switching on the machine or finishing a setting, the machine control changes to the main screen.

This means that the previously selected settings are accepted (if necessary, indicated by signal lights)

and the nominal value of the current (A) is shown in the welding data display on the left. The welding data

display on the right shows the nominal value for the preselected welding voltage (V). The control changes

back to the main screen after 4 s.

4.3.2 Setting the welding current (absolute/percentage)

The welding current is set with the control button (click wheel).

The welding current can be set as a percentage (of the main current) or an absolute value:

TIG:

Start, secondary and end current

MMA: Hot start current

To select, use the parameter

> see 5.11 chapter

in the configuration menu.

4.3.3 Welding parameter setting in the operation sequence

Set a welding parameter in the functional sequence by clicking (select) and turning the click wheel (navi-

gate to the desired parameter). Press again to apply the selected parameter as the setting (corresponding

parameter value and signal light flash). Then turn to set the parameter value.

During welding parameter setting, the parameter value to be set flashes in the left hand display. A para-

meter abbreviation or a deviation in the specified parameter value upwards or downwards is shown on

the right-hand display:

Display

Meaning

Increase the parameter value

To return to the factory settings.

Factory setting (example value = 20)

Parameter is set to optimum value

Decrease the parameter value

To return to the factory settings.