7

2500233-01-05/19 (Translation of the original operating instructions)

Operating Instructions Safety Systems

MGB2-L1…-BR.-… / MGB2-L2…-BR.-… and MGB2-L1…-BP.-… / MGB2-L2…-BP.-…

EN

2. Correct use

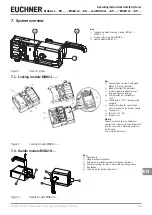

The system consists of at least one locking module MGB2-L1-…/MGB2-L2--… and one handle module MGB2-H…

The safety system MGB2-L.-… is an interlocking device with guard locking (type 4). Devices with unicode evaluation possess

a high coding level, devices with multicode evaluation possess a low coding level.

The locking module can be configured with the aid of DIP switches. Depending on the setting, the locking module behaves

like a BP or BR device (see chapter 2.1. Main differences, MGB2-BP and MGB2-BR on page 8). In addition the guard

locking monitoring can be switched on or off. More detailed information about the possible settings is available in the chapter

13.7. Changing device configuration (using DIP switches) on page 32.

DIP

OFF

ON

With active guard locking monitoring the following applies:

In combination with a movable guard and the machine control, this safety component prevents the guard from being

opened while a dangerous machine function is being performed.

This means:

Ì

Starting commands that cause a dangerous machine function must become active only when the guard is

closed and locked.

Ì

The guard locking must not be unlocked until the dangerous machine function has ended.

Ì

Closing and locking a guard must not cause automatic starting of a dangerous machine function. A separate

start command must be issued. For exceptions, refer to EN ISO 12100 or relevant C-standards.

With inactive guard locking monitoring the following applies:

In combination with a movable guard and the machine control, this safety component prevents dangerous machine

functions from occurring while the guard is open. A stop command is triggered if the guard is opened during the

dangerous machine function. With inactive guard locking monitoring, guard locking must be used only for process

protection.

This means:

Ì

Starting commands that cause a dangerous machine function must become active only when the guard is

closed.

Ì

Opening the guard triggers a stop command.

Ì

Closing a guard must not cause automatic starting of a dangerous machine function. A separate start command

must be issued. For exceptions, refer to EN ISO 12100 or relevant C-standards.

Before the device is used, a risk assessment must be performed on the machine, e.g. in accordance with the following

standards:

Ì

EN ISO 13849-1

Ì

EN ISO 12100

Ì

EN IEC 62061

Correct use includes observing the relevant requirements for installation and operation, particularly based on the following

standards:

Ì

EN ISO 13849-1

Ì

EN ISO 14119

Ì

EN IEC 60204-1

The safety system MGB2 can be combined only with the intended modules in the MGB2 system family.

On the modification of system components, EUCHNER provides no warranty for function.

BR

Locking modules with the configuration MGB2-BR can be integrated into a BR switch chain.

Connection of several devices in a BR switch chain is permitted only using devices intended for series connection

in a BR switch chain. Check the operating instructions for the related device.