1

Operating Instructions

Safety Contact Expansion ESM-ES3..

Correct use

The Safety Contact Expansion ESM-ES3.. in combi-

nation with any safety relay from the EUCHNER ESM

series can be used to produce up to three additional

safety paths per device. An existing system can thus

be expanded practically indefinitely in a modular

manner. Activation takes place via a safety contact

of the safety relay; the ESM-ES3 provides monitor-

ing contacts for error monitoring. The devices can

be used in systems up to safety category 4, PL e

according to EN ISO 13849-1.

Before the device is used, a risk assessment must

be performed on the machine, e.g. according to the

following standards:

f

EN ISO 13849-1

f

EN ISO 12100

f

IEC 62061.

Correct use includes observing the relevant require-

ments for installation and operation, particularly

based on the following standards:

f

EN ISO 13849-1

f

EN 60204-1

f

IEC 62061.

Important!

f

The user is responsible for the integration of

the device in a safe overall system. For this

purpose, the overall system must be validated,

e.g. according to EN ISO 13849-2.

f

The device user must assess and document

remaining risks.

f

If a data sheet is included with the product, the

information on the data sheet applies.

Safety precautions

WARNING

f

Installation and setup of the device must be

performed only by authorized personnel.

f

Observe the country-specific regulations when

installing the device.

f

The electrical connection of the device is only

allowed to be made with the device isolated.

f

The wiring of the device must comply with the

instructions in these operating instructions,

otherwise there is a risk that the safety function

will be lost.

f

It is not allowed to open the device, tamper with

the device or bypass the safety devices.

f

All relevant safety regulations and standards are

to be observed.

f

The overall concept of the control system in

which the device is incorporated must be vali-

dated by the user.

f

Failure to observe the safety regulations can re-

sult in death, severe injuries and serious damage.

f

Note down the version of the device (see type la-

bel

Vx.x.x

) and check it each time prior to setup.

If the version changes, the use of the device in

the overall application must be validated again.

Features

f

3 safe, redundant relay outputs

1 auxiliary contact (error monitoring)

f

Activation via safety relay from the EUCHNER

ESM series

f

Modular, freely configurable safety system

f

Error monitoring by safety relay

f

Ground fault monitoring

f

Indication of the switching state via LED

f

Use up to PL e, SILCL 3, category 4

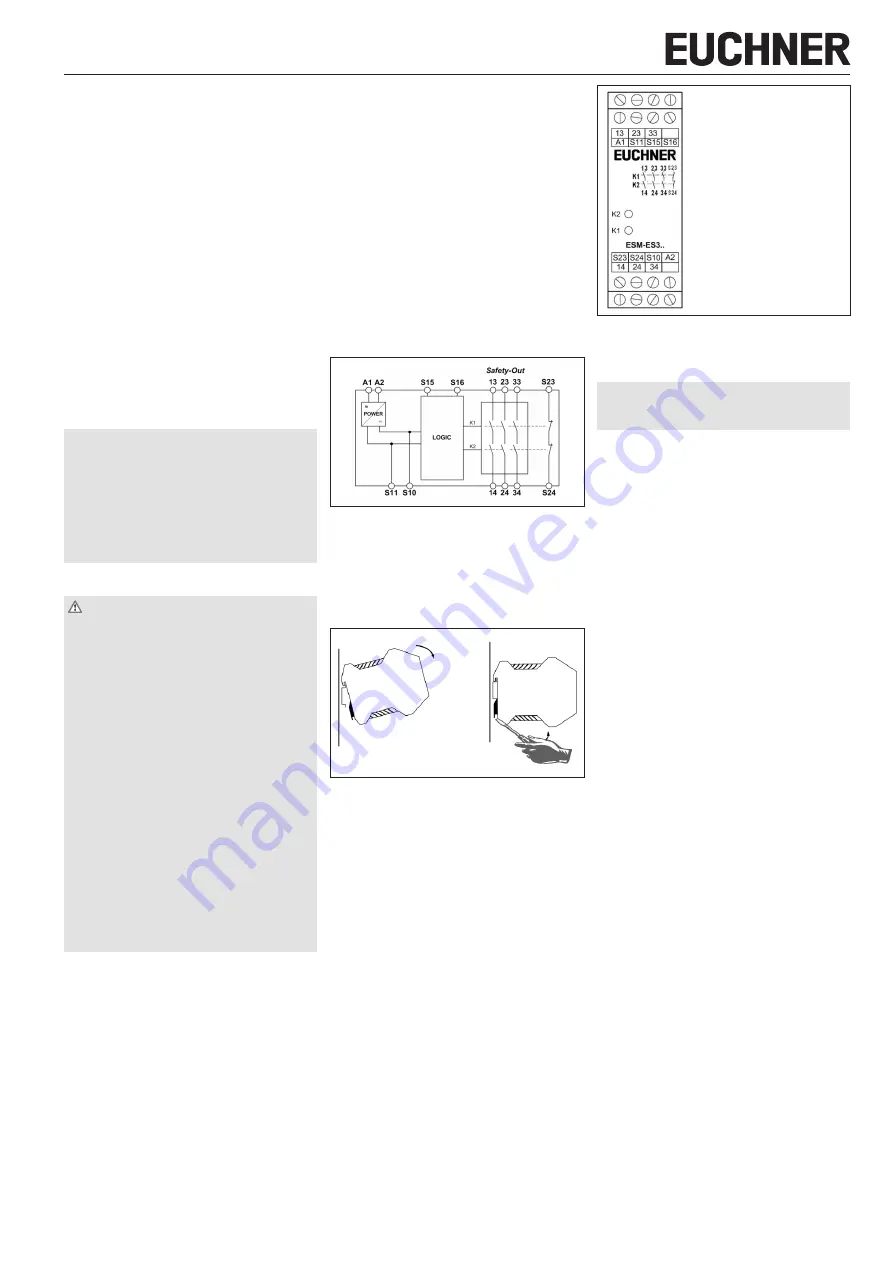

Function

The Safety Contact Expansion ESM-ES3.. in com-

bination with a safety relay from the EUCHNER

ESM series is designed for safe isolation of safety

circuits according to EN 60204-1 and can be

used up to safety category 4, PL e according to

EN ISO 13849-1.

Terminal

S11

(DC 24 V control voltage) is connected

with terminals

S15

and

S16

via the safety contacts

of the safety relay. Starting the safety relay also

activates the ESM-ES3... The safety relay discon-

nects the control voltage when the safety switch is

operated, and the safety contacts of the ESM-ES3..

open immediately.

If a fault occurs in the ESM-ES3.., this is detected by

the safety relay via terminals

S23

and

S24

.

Independent operation without safety relay is

not possible.

Fig. 1: Block diagram for ESM-ES3..

Mounting

As per EN 60204-1, the device is intended for in-

stallation in control cabinets with a minimum degree

of protection of IP54. It is mounted on a 35 mm

mounting rail according to DIN EN 60715 TH35.

Fig. 2: Mounting/removing

Electrical connection

f

When the 24 V version is used, a safety transform-

er according to EN 61558-2-6 or a power supply

unit with electrical isolation from the mains must

be connected.

f

External fusing of the safety contacts must be

provided.

f

A maximum length of the control lines of 1,000 m

with a conductor cross-section of 0.75 mm² must

not be exceeded.

f

The conductor cross-section must not exceed

2.5 mm².

f

If the device does not function after setup, it must

be returned to the manufacturer unopened. Open-

ing the device will void the warranty.

f

PE

(protective earth) must be connected to termi-

nal

S10

on the AC 115/230 V variant. Wiring of

the overall device is to be designed for 115/230 V.

A1

Power supply

A2

Power supply

S11

DC 24 V control voltage

S10

Control line

S15

Control line

S16

Control line

S23

Error monitoring

S24

Error monitoring

13-14

Safety contact 1

23-24

Safety contact 2

33-34

Safety contact 3

Fig. 3: Connections

Setup procedure

Notice

The items listed under

must

be observed during setup.

1. Wiring ESM-ES3..:

Wire the ESM-ES3.. with the EUCHNER safety relay

according to your application (see Fig. 5 and Fig. 6).

2. Wiring safety relay:

Wire the safety relay according to the required

Performance Level determined (see operating

instructions for the safety relay).

3. Wiring feedback loop:

Wire the feedback loop as shown in Fig. 7 and Fig. 8.

4. Wiring power supply:

Connect the power supply to terminals

A1

and

A2

Attention:

Wiring only in de-energized state.

5. Starting the device:

Switch the operating voltage on.

Attention:

If the

Automatic start

behavior is set

on the safety relay, the safety contacts will close

immediately.

If the

Monitored manual start

behavior is set, close

the start button to close the safety contacts.

The LEDs

K1

and

K2

on the safety relay and on the

ESM-ES3.. illuminate.

6. Activating safety function:

Open the emergency stop circuit by actuating the

connected safety switch. The safety contacts of the

safety relay and the ESM-ES3.. open immediately.

7. Reactivating:

Close the emergency stop circuit. If

Automatic start

is selected on the safety relay, the safety contacts

will close immediately.

If the

Monitored manual start

behavior is set, close

the start button on the safety relay to close the safe-

ty contacts of the safety relay and the ESM-ES3...