83

sEctIoN 4

opEratIoN

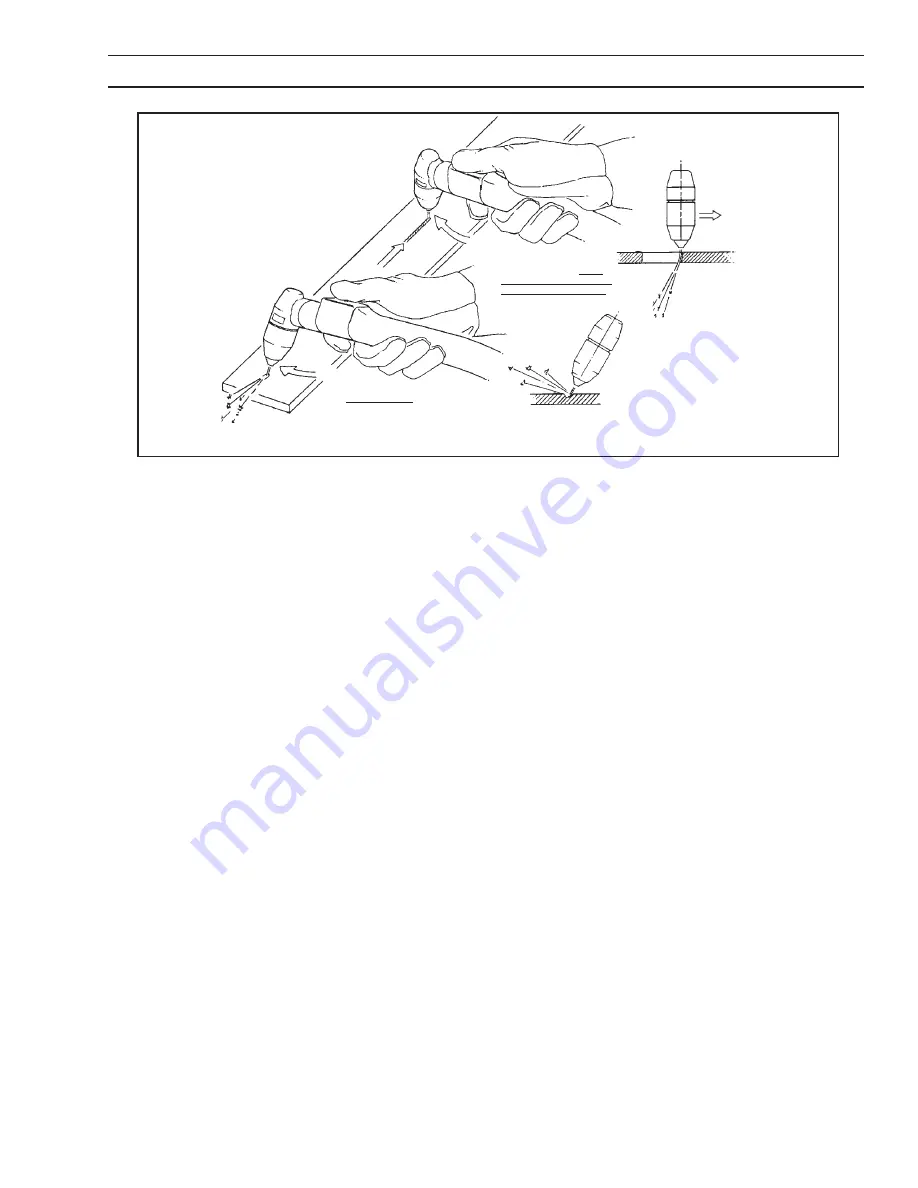

figure 4-5. piercing technique using the pt-32Eh

a. Insufficient penetration.

1. Current too low.

2. Cutting speed too fast.

3. Damaged cutting nozzle.

4. Improper air pressure.

5. Low air flow rate.

B. Main arc Extinguishes.

1. Cutting speed too slow.

2. Worn electrode.

c. Dross formation. (In some materials and thick-

nesses, it may be impossible to get dross-free

cuts.)

1. Current too low.

2. Cutting speed too fast or too slow.

3. Improper air pressure.

4. Faulty nozzle or electrode.

5. Low air flow rate.

D. Double arcing. (Damaged Nozzle Orifice.)

1. Low air pressure.

2. Damaged cutting nozzle.

WHEN THE ARC BREAKS

THROUGH THE WORK, BRING

THE TORCH TO AN UPRIGHT PO-

SITION AND PROCEED TO CUT.

TO START A PIERCE, TILT THE TORCH TO

PREVENT MOLTEN MATERIAL FROM COM-

ING BACK AGAINST AND DAMAGING

THE TORCH.

1

2

4.4 coMMoN cuttINg proBlEMs

Listed below are common cutting problems followed by the probable cause of each. If problems are determined to be

caused by the Powercut 875, refer to the maintenance section of this manual. If the problem is not corrected after referring

to the maintenance section, contact your ESAB distributor.

3. Loose cutting nozzle.

4. Heavy spatter accumulation on nozzle.

E. uneven arc.

1. Damaged cutting nozzle or worn electrode.

f. unstable cutting conditions.

1. Incorrect cutting speed.

2. Loose cable or hose connections.

3. Electrode and/or cutting nozzle in poor condition.

g. Main arc Does Not strike.

1. Worn electrode.

2. Loose connections.

3. Worn cable not attached.

h. poor consumable life.

1. Improper gas pressure.

2. Contaminated air supply.

3. Low air flow rate.

Summary of Contents for Powercut 875

Page 4: ...4 table of contents ...

Page 8: ...8 OBSAH ...

Page 18: ...18 ODDÍL 3 INSTALACE ...

Page 24: ...24 ODDÍL 4 OBSLUHA ...

Page 28: ...28 INDHOLDSFORTEGNELSE ...

Page 38: ...38 SEKTION 3 BETJENING ...

Page 44: ...44 SEKTION 4 BETJENING ...

Page 48: ...48 INHOUDSOPGAVE ...

Page 58: ...58 HOOFDSTUK 3 INSTALLATIE ...

Page 64: ...64 HOOFDSTUK 4 BEDIENING ...

Page 68: ...68 table of contents ...

Page 78: ...78 SECTION 3 INSTALLATION ...

Page 84: ...84 SECTION 4 OPERATION ...

Page 88: ...88 SISUKORD ...

Page 98: ...98 OSA 3 PAIGALDAMINE ...

Page 104: ...104 OSA 4 KASUTAMINE ...

Page 108: ...108 SISÄLLYSLUETTELO ...

Page 118: ...118 KAPPALE 3 ASENNUS ...

Page 124: ...124 KAPPALE 4 KÄYTTÖ ...

Page 128: ...128 table DES MATIÈRES ...

Page 138: ...138 SECTION 3 INSTALLATION ...

Page 144: ...144 SECTION 4 FONCTIONNEMENT ...

Page 148: ...148 INHALTSANGABE ...

Page 158: ...158 ABSCHNITT 3 INSTALLIERUNG ...

Page 164: ...164 ABSCHNITT 4 BEDIENUNG ...

Page 168: ...168 TARTALOMJEGYZÉK ...

Page 178: ...178 3 SZAKASZ ÖSSZESZERELÉS ...

Page 184: ...184 4 SZAKASZ MŰKÖDÉS ...

Page 188: ...188 INDICE ...

Page 198: ...198 SEZIONE 3 INSTALLAZIONE ...

Page 204: ...204 SEZIONE 4 FUNZIONAMENTO ...

Page 216: ...216 section 6 replacement parts ...

Page 217: ...217 section 6 replacement parts ...

Page 218: ...218 section 6 replacement parts ...

Page 219: ...219 section 6 replacement parts ...

Page 220: ...220 section 6 replacement parts ...

Page 221: ...221 section 6 replacement parts ...

Page 222: ...222 section 6 replacement parts ...

Page 223: ...223 section 6 replacement parts ...

Page 224: ...224 section 6 replacement parts ...

Page 225: ...225 section 6 replacement parts ...

Page 226: ...226 section 6 replacement parts ...