Pr

o

-

C

Series

3

Receiving & Inspection

Upon delivery, confi rm that the quantity and model(s)

received matches the Bill of Lading. If there is any

discrepancy, immediately notify ERV Systems.

Inspect the skidded PRO-C(s) for signs of damage. If

damage is suspected, sign the Bill of Lading “damaged.” If

no visible damage is apparent, the unit should be properly

lifted and stored until installation.

While skidded, the PRO-C can be lifted by a forklift

using the skid. Once removed from the skid, lifting must

only be performed with spreader bars, cable and hooks. Do

not attempt to lift the PRO-C by grasping the hoods.

Storage

If the PRO-C is to be stored for any time before installation,

it must be protected from the weather. Indoor storage is

recommended. The unit has openings provided for ducting.

These openings make the internal equipment (motors,

belts, fans and insulation) vulnerable to inclement weather

conditions (prior to installation) and can cause standing

water to accumulate inside the enclosure. This is to be

absolutely avoided.

H

L

W

Table 1. Weights & Dimensions

Model

L

(in)

H

(in)

W

(in)

Net

Weight*

(lbs)

PRO-C-1000

47.86

30.19

31.38

350

PRO-C-2400

54.75

38.81

40.38

475

*The package weighs approximately 100 lbs. more than

the net weight.

Overall Dimensions

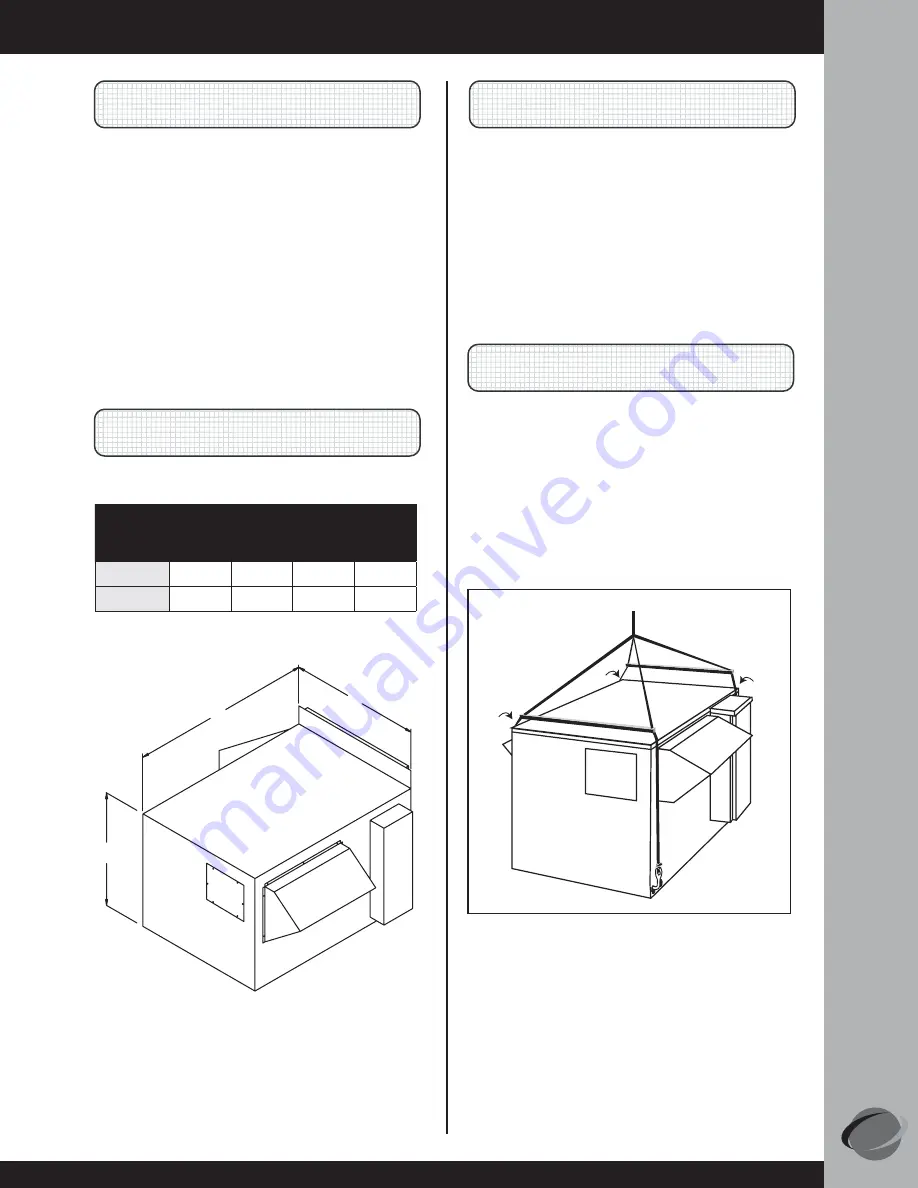

Lifting Technique

When rigging the PRO-C, spreader bars must be used.

Padding must be inserted between the straps and the unit

to avoid scratching the paint. Lifting holes are provided at

four points located on the base perimeter of the PRO-C

unit. The weight shown in Table 1 may be used as maximum

weight for rigging.

padding

padding

padding

NOTE:

Prior to starting unit:

1. Open access door

2. Remove loose parts shipped inside.

Figure 4. Correct lifting technique using spreader bars.