Models 110X, 210X, 310X, 360X, 410X

Safety and operating instructions

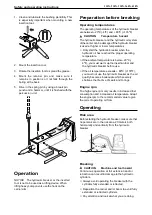

Insertion tool

Selecting the right insertion tool

Conical moil point

1. Drive out the spring pin by using a break pin

punch and a hammer. Press the retainer pin out

from the hole at the back upwards until you can

remove it through the hole on the front side.

Chisels and spades

>

Very good penetration

>

Regular spread of wedge

action

>

No torsion effect

>

Very good spread of wedge

action

>

Good penetration

>

Torsion effect

Blunt tool

>

Very good energy

application

>

Optimum breaking effect

>

No torsion effect

NOTICE

Dismount the insertion tool with a

lifting strap to reduce the risk of crushed body

parts. Some insertion tools are heavy, therefore

lift out the insertion tool in a safe way.

2. Check that the spring pin is not worn out or

damaged. Change if necessary.

Mounting and dismounting the insertion

tool

WARNING

Running engine

Changing the inserted tool or accessories while the

carrier's engine is running can cause serious injury.

►

Secure the carrier against involuntary activation.

Before you start mounting or dismounting the

insertion tool, do the following:

1. Place the hydraulic breaker on timber support

blocks. The boring on the back side of the

hydraulic breaker has to remain free.

2. Shut off the carrier's engine.

3. Remove two plugs from the hammer box, the

first at the split pin and the second at the retainer

pin.

Dismounting the insertion tool:

Mounting the insertion tool

Summary of Contents for 110X

Page 1: ...Safety and operating instructions Hydraulic breakers Models 110X 210X 310X 360X 410X ...

Page 4: ...110X 210X 310X 360X 410X Safety and operating instructions ...

Page 25: ...Models 110X 210X 310X 360X 410X ...

Page 27: ...NEW STYLE HYDRAULIC BREAKER PARTSINFORMATION ...

Page 29: ...MINI HYDRAULIC BREAKER NEW STYLE X SERIESINFORMATION ...

Page 30: ...NOTES ...

Page 31: ...NOTES ...

Page 32: ...2012 05 No 9800 1050 01b Copyright ERSKINE ATTACHMENTS LLC ...