Shaking and Replacing

Ink Supply Units

Shaking

Timing and frequency of shaking

c

Important:

Due to ink characteristics, the ink supply units of

this printer are prone to sedimentation

(components settling to the bottom of the liquid).

If ink settles, tint unevenness and nozzle clogs occur.

Shake a new ink supply unit before installing it.

After installing it in the ink unit, remove and

shake it periodically.

❏

When replacing

Approx. 10 times in 10 seconds

You do not need to shake the OP, ML, or cleaning

ink supply units.

❏

Once every week

Remove any tray whose LED light is flashing blue,

and then shake the ink supply unit tray. To

maintain print quality, do not continue using

them when they are flashing blue.

Approx. 5 times in 5 seconds

Shaking method

A

Make sure the printer is on, and then pull the

ink supply unit tray that needs to be shaken out

of the ink unit.

Any ink supply unit whose LED light is flashing

blue needs to be shaken.

c

Important:

Place your hand on the bottom of the ink

supply unit tray while removing it. If you use

only one hand, the weight of the ink supply

unit tray may cause it to fall, and be

damaged, as you remove it.

Note:

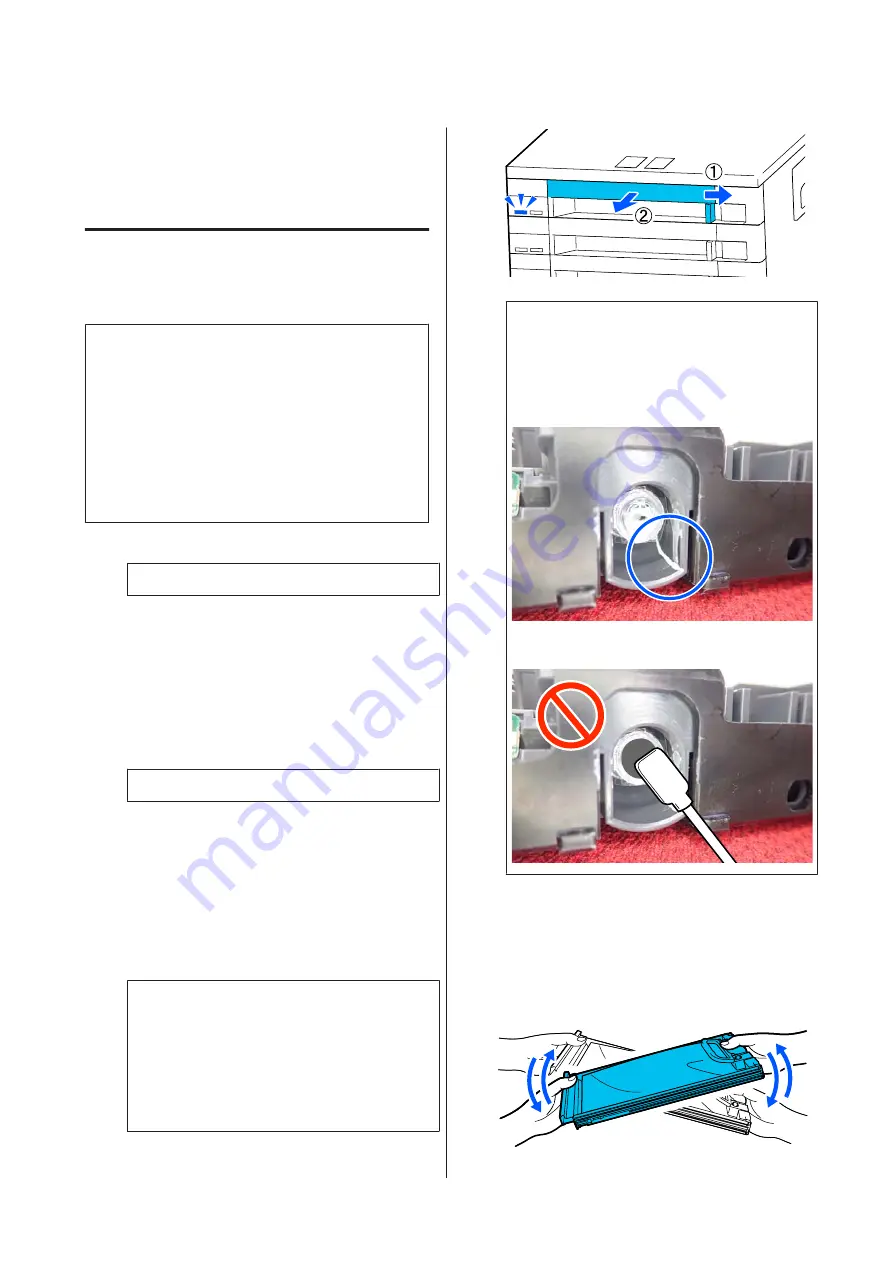

While the ink supply unit tray is pulled out, check

the ink supply ports of the ink supply units. If ink

has dripped from the port or accumulated at the

bottom as shown in the photo, wipe it off using a

cleaning stick.

Do not touch the ink supply ports while wiping.

B

While the ink supply unit is in the ink supply

unit tray, as shown in the illustration below,

shake it thoroughly by tilting it up and down at

about a 60 degree angle 5 times in 5 seconds.

You do not need to shake the OP, ML, or

cleaning ink supply units.

SC-R5000 Series/SC-R5000L Series User's Guide

Maintenance

87