Pre-treatm

ent Liquid

Applicatio

n Area

Temperatu

re

Time

Pressure

*1

A4 and

smaller

170 °C

45 secs.

4.2 N/cm

2

Larger than

A4

170 °C

45 to 90

*2

secs.

*1The optimum conditions vary depending on the type of heat

press such as the manual adjustment type. Be sure to test the

ink fixation result in advance to find the right pressure.

*2 If it is not completely dry after 45 seconds, extend the

duration while carefully checking if the pre-treatment liquid

is dry.

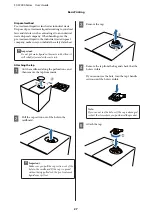

c

Important:

Do not wet the T-shirt or leave it in a humid

location for a long time after fixating the

pre-treatment liquid. White ink may sink in the wet

sections and cause unevenness in color.

If the T-shirt is left for an extended period of time in

such conditions, press for 5 to 10 seconds to dry it

just before printing.

Note:

If traces of the pre-treatment liquid are visible, try

washing in water; however, the effects depend on the

material of the T-shirt.

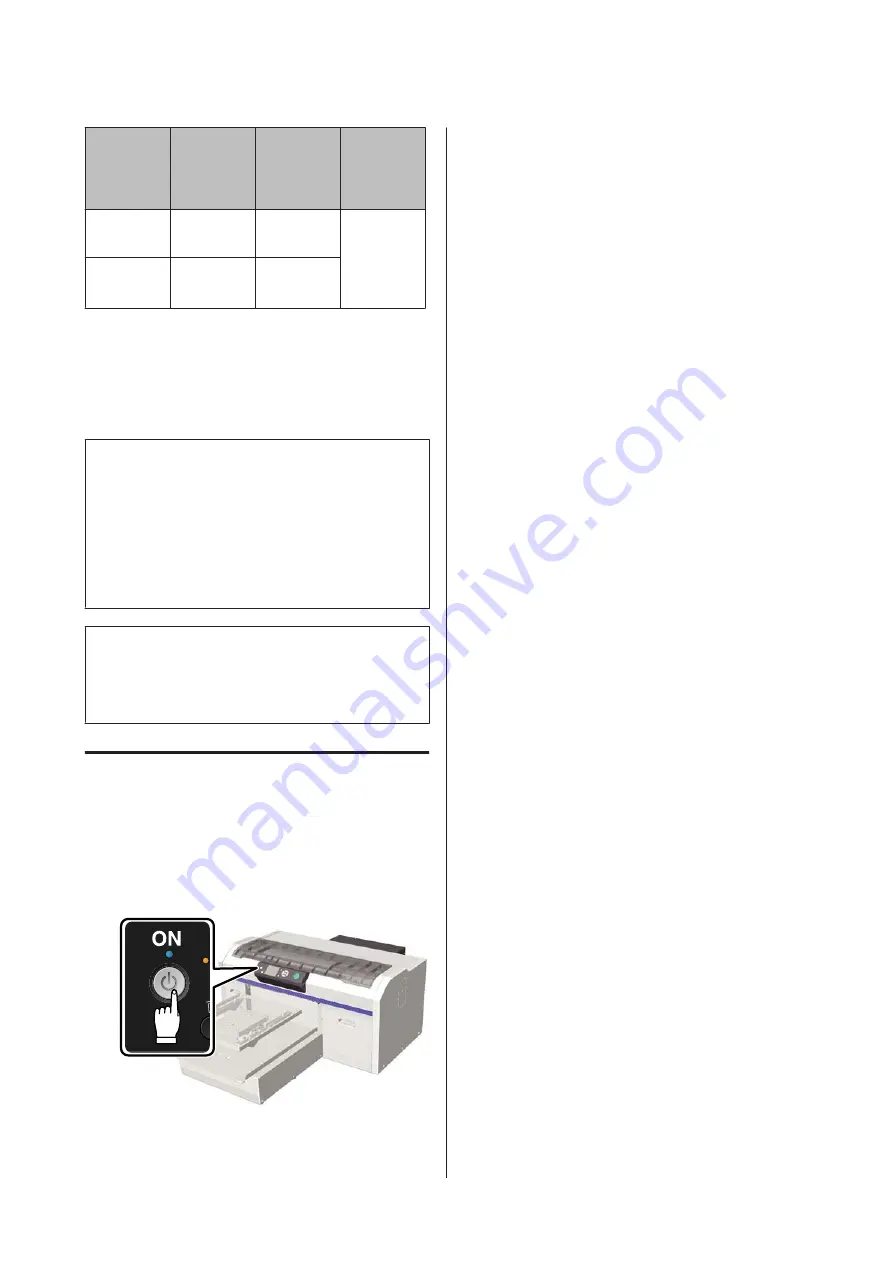

Preparing the Printer

Check the printer's status before transmitting print

data. We recommend checking that the print head

nozzles are not clogged.

A

Turn the printer on.

B

When White ink is loaded, shake the White ink

cartridge.

U

“Replacing and Shaking Cartridges” on

C

Check for clogged nozzles.

U

“Checking for clogged nozzles” on

SC-F2000 Series User’s Guide

Basic Printing

30