The Parallel Interface

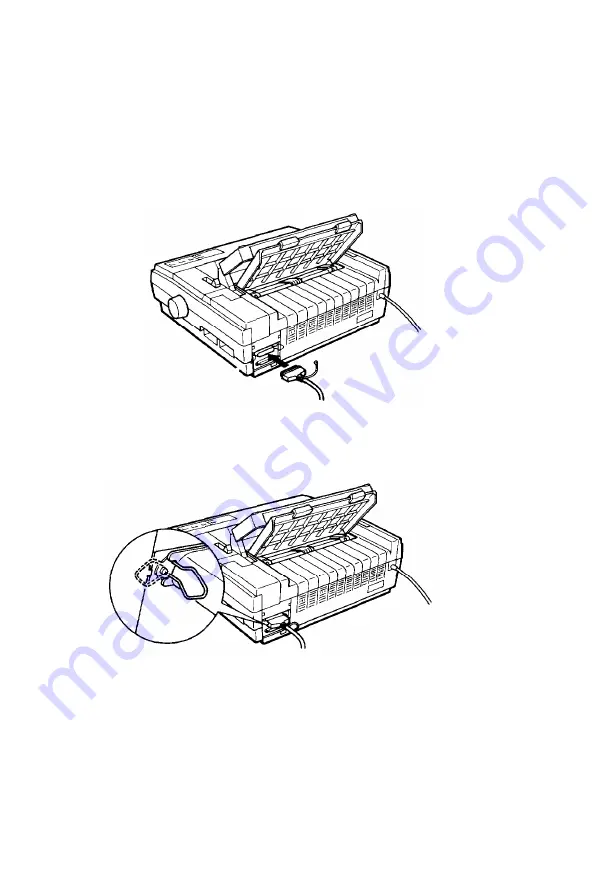

Connect the parallel interface cable as described below:

1. Make sure that both your printer and computer are turned off.

2. Plug the cable connector securely into the printer.

3. Squeeze the wire clips together until they lock in place on either

side of the connector.

1-28

Setting Up

the

Printer

Summary of Contents for LQ-860 - Impact Printer

Page 1: ...User s Manual EPSON 4 0 0 8 1 2 3 6 0 1 0 3 ...

Page 2: ...E P S O N L Q 8 6 0 User s Manual ...

Page 197: ...8 Close the printer cover and the paper guide cover 6 8 Maintenance ...

Page 299: ...Appendix Proportional Width Table A 2 Character Tables A 6 A l ...

Page 305: ......

Page 322: ......

Page 324: ......