Confidential

Confidential

Adjus

Adjus

t

t

m

m

e

e

nt

nt

Adjus

Adjus

t

t

m

m

e

e

nt

nt

Pr

Pr

o

o

gr

gr

a

a

m

m

61

61

2.

2. Con

Connec

nect the pr

t the print

inter an

er and the P

d the PC with t

C with the US

he USB cab

B cable.

le.

3.

3. Sta

Start th

rt the ad

e adju

just

stme

ment p

nt pro

rogr

gram

am..

4.

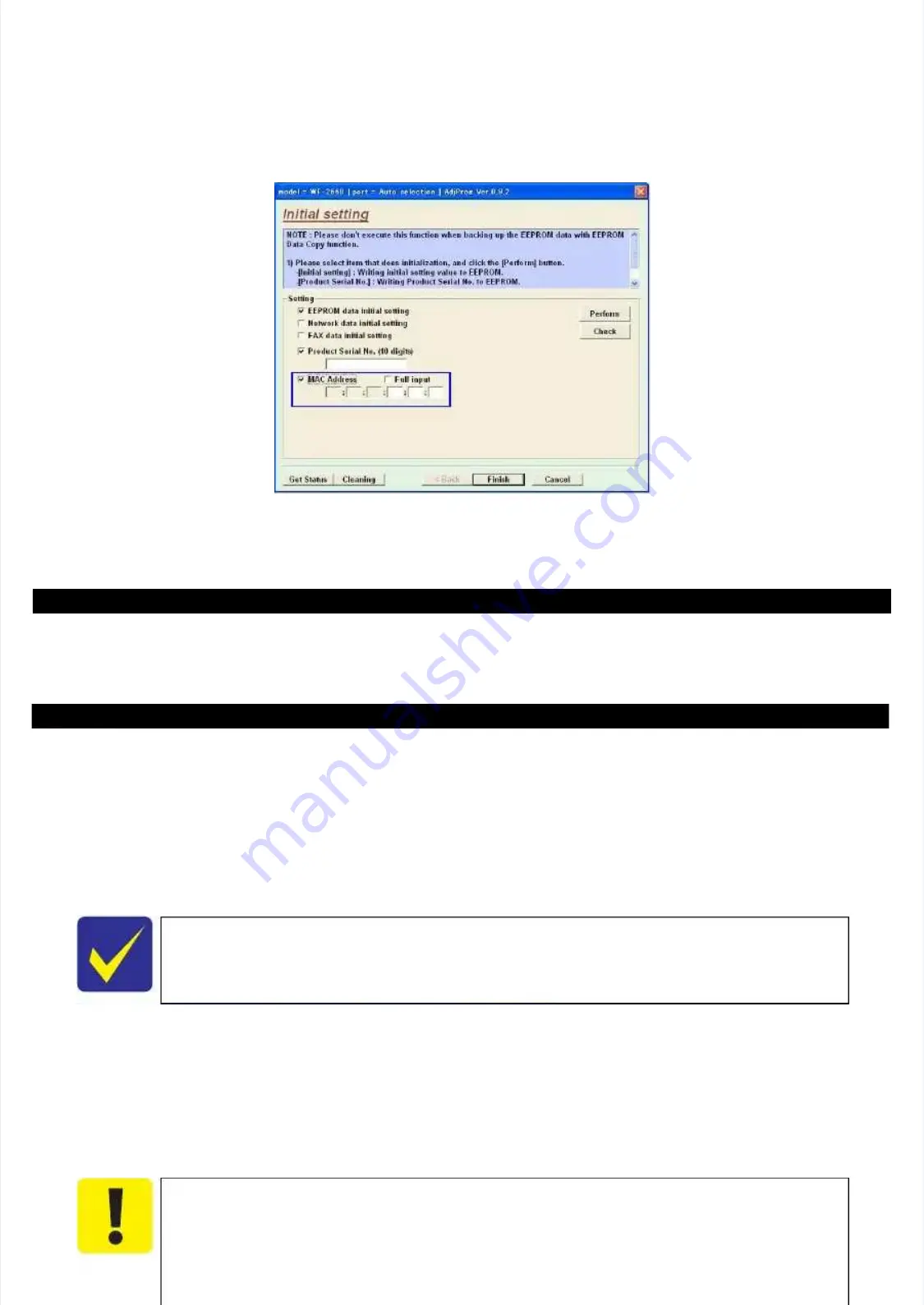

4. Select th

Select the “Init

e “Initial Sett

ial Setting” fr

ing” from the m

om the menu. Th

enu. The initia

e initial settin

l setting scree

g screen appe

n appears.

ars.

5.

5. Enter th

Enter the last six dig

e last six digits of MAC ad

its of MAC address in

dress into the MAC ad

to the MAC address ent

dress entry field

ry field, and click t

, and click the Perfo

he Perform butto

rm button.

n.

6.

6. Select th

Select the networ

e network status she

k status sheet print m

et print menu on the pr

enu on the printer

inter’s contr

’s control panel

ol panel, and prin

, and print the sheet. C

t the sheet. Check the MA

heck the MAC

C

address printed on the sheet to see if it is correct.

address printed on the sheet to see if it is correct.

Figu

Figure 3-2.

re 3-2. MAC A

MAC Addre

ddress Set

ss Setting Sc

ting Screen

reen

E

E

p

p

s

s

o

o

n

n

E

E

T

T

-

-

4

4

5

5

5

5

0

0

,

,

L

L

6

6

5

5

5

5

/

/

6

6

5

5

6

6

R

R

e

e

v

v

i

i

s

s

i

i

o

o

n

n

B

B

3.3

3.3 De

Detai

tails o

ls of Ad

f Adju

justm

stmen

ents

ts

This section provides adjustment procedures for which explanation in details

This section provides adjustment procedures for which explanation in details is necessary. See

is necessary. See "3.1 Required

"3.1 Required

Adjustments (p55)"

Adjustments (p55)"

for the adjustments not

for the adjustments not explained here.

explained here.

3.3

3.3.1

.1 Che

Checki

cking t

ng the P

he Plat

laten G

en Gap

ap

This section describes the procedure for checking the

This section describes the procedure for checking the platen gap (PG).

platen gap (PG).

Tools

Tools

Thickness gauges for PG check: 1.48 mm gauge, 1.76 mm gauge

Thickness gauges for PG check: 1.48 mm gauge, 1.76 mm gauge

Teflon tape: Commercially available product (thickness: 0.08

Teflon tape: Commercially available product (thickness: 0.08 mm)

mm)

3.3

3.3.1.

.1.1

1 Pre

Prepar

parati

ation

on

This section describes how and

This section describes how and what to prepare for the preparation before starting t

what to prepare for the preparation before starting the PG check.

he PG check.

Modification of the thickness gauges

Modification of the thickness gauges

The standard range of the PG is as follows:

The standard range of the PG is as follows:

•• S

Sta

tan

nd

dar

ard

d: 1

: 1.7

.7

±

±

0.14 mm

0.14 mm

Check the platen gap before installing the

Check the platen gap before installing the CR Scale.

CR Scale.

The Printhead of this printer has

The Printhead of this printer has an integral structure of the

an integral structure of the Printhead Cover and

Printhead Cover and

Printhead nozzle surface. Therefore, if the thickness gauge touches the

Printhead nozzle surface. Therefore, if the thickness gauge touches the nozzle surface in

nozzle surface in

the same way as performed in

the same way as performed in the traditional procedure, the nozzle surface may be

the traditional procedure, the nozzle surface may be

damaged. When checking the platen gap, make sure to apply Teflon tape (thickness : 0.08

damaged. When checking the platen gap, make sure to apply Teflon tape (thickness : 0.08

mm) on all the

mm) on all the thickness gauges used for checking the Platen Gap i

thickness gauges used for checking the Platen Gap in advance.

n advance.

Use commercially available Teflon tape of 0 08

Use commercially available Teflon tape of 0 08 mm in thickness

mm in thickness