16

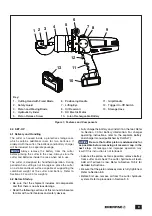

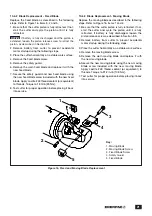

10.0 MAINTENANCE

10.1 Preparation for Maintenance

All cutter maintenance procedures must be performed

under the following conditions:

• Material must be removed from the cutting head.

• The battery must be removed from the cutter.

• The cutter must be given time to cool to prevent burns.

• Procedures must be performed in a suitable work

environment in accordance with all current safety

regulations and/or laws in your country or region.

• The cutter must be cleaned thoroughly before

maintenance procedures are performed.

• Suitable personal protective equipment (PPE) must be

used and/or worn while performing any work.

NOTICE:

WARNING

The cutter must sometimes be

operated in order to complete a maintenance or

repair procedure being performed, or to prepare it

for a procedure that is about to be performed.

However, to prevent startup while persons are

working on the cutter, always remove the battery

from the cutter before beginning any procedure

steps that require use of tools and/or physical

contact with the cutter. Failure to observe this

precaution may result in death or serious personal

injury.

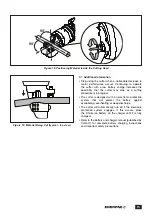

NOTICE:

WARNING

Ensure that cutter blade safety guard

has been correctly reinstalled before placing the

cutter back into service after maintenance

procedures are completed. Failure to reinstall this

guard could result in serious personal injury.

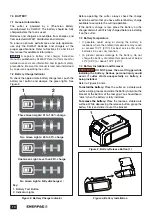

10.2 Periodic Maintenance Chart

Refer to the Periodic Maintenance Chart (Table 1) for a

list of various routine checks and procedures.

10.3 Cleaning

• Clean the cutter using a dry cloth or compressed air.

For plastic surfaces, use a cloth slightly dampened

with water.

NOTICE:

CAUTION

To prevent possible injury, always wear

safety glasses or face mask when using compressed

air.

• Be sure there are no traces of oil, grease or corrosive

substances on the tool, especially on the grips.

• Use a damp cloth and soapy water to clean plastic

components.

• Do not use gasoline or thinner to clean the tool.

10.4 Fasteners

Periodically check all screws, nuts and other fasteners

for proper tightness. Tighten any loose fasteners.

Replace any worn or damaged fasteners. This should

be performed periodically or every day in the event of

frequent or prolonged cutter operation.

NOTICE

Failure to check and tighten fasteners as

required may result in serious damage to the cutter.

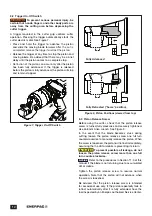

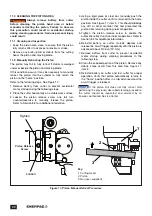

10.5 Cutter Hydraulic System

The cutter contains a small hydraulic pump and oil

reservoir with rubber diaphragm. The oil level must be

periodically checked and additional oil must be added if

the oil level is low. In addition, the oil must be completely

changed at the specified interval. Refer to the Periodic

Maintenance Chart (Table 1).

Table 1, Periodic Maintenance Chart

Time Interval

Maintenance Operation

Method

Maint. Level

Every 8 hours of

operation:

Check the cutter for loose,

damaged or worn parts.

Check for oil leaks. Tighten,

replace or repair as required.

Visual

Operator

Check the tightening

torque of screws and bolts.

Replace any missing screws

or bolts.

(Refer to instructions in Section 10.4)

Operator

Check fixed and moving

blades for wear.

(Refer to instructions in Section 10.6.1) Operator

Every 1600 hours

of operation:

Change the hydraulic oil.

(Refer to instructions in Section 10.5.3) Service Center

As required:

Clean the cutter piston.

(Refer to instructions in Section 11.0)

Operator

Replace fixed and moving

blades.

(Refer to instructions in Section 10.6.2

and 10.6.3)

Operator

Summary of Contents for EBC20B

Page 25: ...25 Notes...

Page 26: ...26 Notes...

Page 27: ...27 Notes...

Page 28: ...199 Gateway Ct Columbus WI 53925 USA www enerpac com Made in Italy WWW ENERPAC COM...