Proline Prosonic Flow P

Installation

Hauser

37

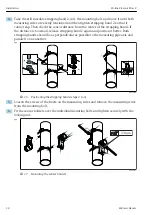

2. Turn the housing to the desired position.

3. Tighten the securing screws.

5.2.7

Turning the display module

The display module can be turned to optimize display readability and operability.

N

ic

h

t

u

n

te

r

ar

e

ö

ffn

e

n

+

E

ESC

–

1.

2.

N

ic

h

t

u

n

te

r

ar

e

ö

ffn

e

n

+

E

ESC

–

3.

3 mm

+

E

ESC

–

A0030035

1. Depending on the device version: Loosen the securing clamp of the connection

compartment cover.

2. Unscrew the connection compartment cover.

3. Turn the display module to the desired position: max. 8 × 45° in each direction.

4. Screw on the connection compartment cover.

5. Depending on the device version: Attach the securing clamp of the connection

compartment cover.

5.3

Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature

• Inlet run conditions

• Ambient temperature

• Measuring range

Has the correct orientation for the sensor been selected → 11?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Are the sensors correctly connected to the transmitter (upstream/downstream) → 2, 11?

Are the sensors correctly mounted (distance, 1 traverse, 2 traverses) ?

Summary of Contents for Proline Prosonic Flow P

Page 39: ......