Menu 13

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

240

Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 10

Rigid position control

In rigid position control the position error is always accumulated. This means that, if for example, the slave shaft is slowed down due to excessive

load, the target position will eventually be recovered by running at a higher speed when the load is removed.

Non-rigid position control

In non-rigid position control the position loop is only active when the 'At Speed' condition is met (see Pr

on page 53). This allows slippage to

occur while the speed error is high. It may be necessary to increase the ‘At Speed’ window in Pr

3.06

and Pr

3.07

with some lower resolution

feedback devices.

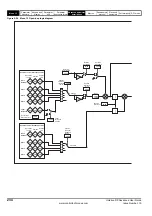

Velocity feed forward

The position controller can generate a velocity feed forward value from the speed of the reference encoder. The feed-forward value is passed to menu

1, and so ramps may be included if required. Because the position controller only has a proportional gain, it is necessary to use velocity feed-forward

to prevent a constant position error that would be proportional to the speed of the reference position.

If for any reason the user wishes to provide the velocity feed forward from a source other than the reference position, the feed forward system can be

made inactive, i.e. Pr

13.10

= 2 or 4. The external feed forward can be provided via Menu 1 from any of the frequency/speed references. However, if

the feed forward level is not correct a constant position error will exist.

Relative jogging

If relative jogging is enabled the feedback position can be made to move relative to the reference position at the speed defined by Pr

13.17

.

Orientation

If Pr

13.10

is 5 the drive orientates the motor following a stop command. If hold zero speed is enabled (Pr

6.08

= 1) the drive remains in position

control when orientation is complete and holds the orientation position. If hold zero speed is not enabled the drive is disabled when orientation is

complete.

If Pr

13.10

is 6 the drive orientates the motor following a stop command and whenever the drive is enabled provided that hold zero speed is enabled

(Pr

6.08

= 1). This ensures that the spindle is always held in the same position following the drive being enabled.

Parameter

value

Mode

Feed forward

active

0

Position controller disabled

1

Rigid position control

9

2

Rigid position control

3

Non-rigid position control

9

4

Non-rigid position control

5

Orientation on stop

6

Orientation on stop and when drive enabled

Speed

t

Reference

Actual

Equal Areas

Reference

Actual

Speed

Summary of Contents for unidrive sp

Page 419: ......

Page 420: ...0471 0002 10 ...