Instruction Manual

IM-106-350, Rev 2.2

July 2008

1-7

Oxymitter 5000

7. The electronics are adaptable for line voltages from 90-250 VAC;

therefore, no configuration is necessary.

8. The Oxymitter 5000 membrane keypad is available in five languages:

English

French

German

Italian

Spanish

9. An operator can calibrate and diagnostically troubleshoot the Oxymitter

5000 in one of four ways:

a. Membrane Keypad. The membrane keypad, housed within the right

side of the electronics housing, provides fault indication by way of

flashing LEDs. Calibration can be performed from the membrane

keypad.

b. LOI. The optional LOI takes the place of the membrane keypad and

allows local communication with the electronics. Refer to Section 6

for more information.

c. FOUNDATION fieldbus Interface. The Oxymitter 5000's output

carries a signal containing the oxygen level encoded in digital format.

This digital output can also be used to communicate with the

Oxymitter and access all of the Oxymitter’s status information.

d. Optional IMPS 4000. The Programmable Logic Controller (PLC) in

the IMPS 4000 provides fault indications using flashing LEDs and

LCD display messages. Refer to the IMPS 4000 Intelligent

Multiprobe Test Gas Sequencer Instruction Manual for more

information.

Handling the Oxymitter

5000

System Considerations

Prior to installing your Oxymitter 5000, make sure you have all the

components necessary to make the system installation. Ensure all the

components are properly integrated to make the system functional.

After verifying that you have all the components, select mounting locations

and determine how each component will be placed in terms of available line

voltage, ambient temperatures, environmental considerations, convenience,

and serviceability.

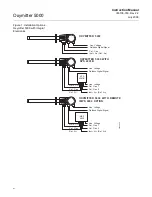

Figure 1-5 shows a typical system wiring.

A typical system installation for an Oxymitter 5000 with integral electronics is

shown in Figure 1-6. A typical system installation for an Oxymitter 5000 with

remote electronics is shown in Figure 1-7.

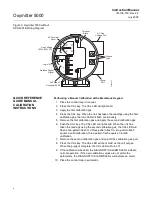

It is important that printed circuit boards and integrated circuits are handled only when

adequate antistatic precautions have been taken to prevent possible equipment damage.

The Oxymitter 5000 is designed for industrial applications. Treat each component of the

system with care to avoid physical damage. Some probe components are made from

ceramics, which are susceptible to shock when mishandled.

Summary of Contents for Oxymitter 5000

Page 2: ......

Page 6: ......

Page 12: ......

Page 22: ...Oxymitter 5000 xii Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 42: ...Oxymitter 5000 1 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 62: ...Oxymitter 5000 2 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 74: ...Oxymitter 5000 4 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 78: ...Oxymitter 5000 5 4 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 94: ...Oxymitter 5000 7 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 140: ...Oxymitter 5000 9 22 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 184: ...Oxymitter 5000 B 2 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 204: ...Oxymitter 5000 D 14 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 222: ...Oxymitter 5000 E 18 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 224: ...Instruction Manual IM 106 350 Rev 2 2 July 2008 Index 2 Oxymitter 5000 ...