© 2017 Emerson Climate Technologies, Inc.

8

AE4-1372 R4

tube (available from Emerson) and install it in a system

with the longest connecting lines that are approved for

the system. The minimum on time becomes the time

required for oil lost during compressor start-up to return

to the compressor sump and restore a minimal oil level

that will ensure oil pick-up through the crankshaft.

Cycling the compressor for a shorter period than this, for

instance to maintain very tight temperature control, will

result in progressive loss of oil and damage to the

compressor.

ASSEMBLY LINE PROCEDURES

Installing the Compressor

Copeland Scroll compressors leave the factory

dehydrated and with a positive dry air charge. Plugs

should not be removed from the compressor until the

compressor has had sufficient time to warm up if stored

outside and is ready for assembly in the unit. The

suggested warm up time is one hour per 4°F (2K)

difference between outdoor and indoor temperature. It

is suggested that the larger suction plug be removed

first to relieve the internal pressure. Removing the

smaller discharge plug could result in a spray of oil out

of this fitting since some oil accumulates in the head of

the compressor after Emerson’s run test. The inside of

both fittings should be wiped with a lint free cloth to

remove residual oil prior to brazing. A compressor

containing POE oil should never be left open longer than

5 minutes.

Assembly Line Brazing Procedure

Following are

the proper procedures for brazing the

suction and discharge lines to a scroll compressor. It is

important to flow nitrogen through the system while

brazing all joints during the system assembly process.

Nitrogen displaces the air and prevents the formation of

copper oxides in the system. If allowed to form, the

copper oxide flakes can later be swept through the

system and block screens such as those protecting

capillary tubes, thermal expansion valves, and

accumulator oil return holes. Any blockage of oil or

refrigerant may damage the compressor resulting in

failure.

New Installations

•

The copper-coated steel suction tube on scroll

compressors can be brazed in approximately the

same manner as any copper tube.

•

Recommended brazing materials: Any SIL-FOS®

material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is

acceptable.

•

Be sure suction tube fitting I.D. and suction tube

O.D. are clean prior to assembly. If oil film is

present wipe with denatured alcohol, Dichloro-

Trifluoroethane or other suitable solvent.

•

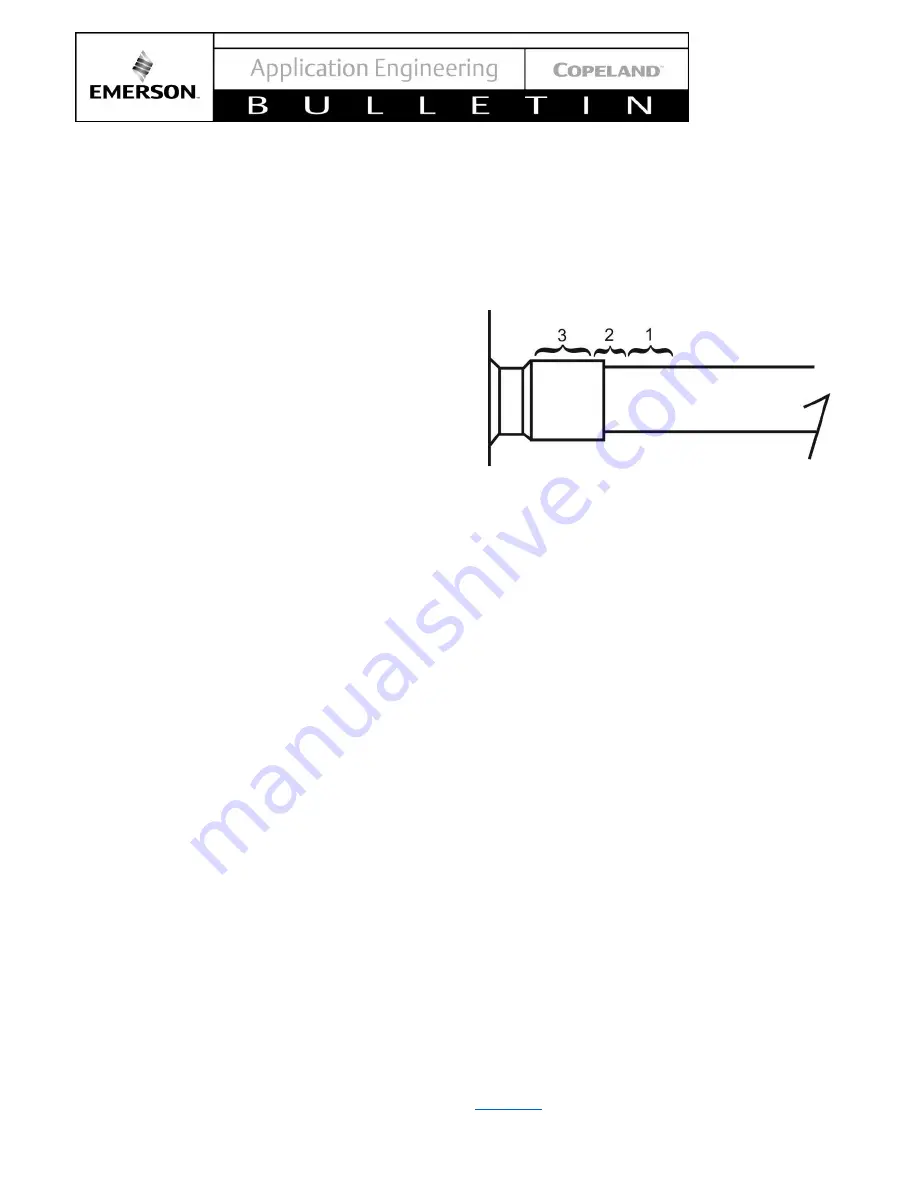

Using a double-tipped torch apply heat in Area 1.

As tube approaches brazing temperature, move

torch flame to Area 2.

Scroll Suction Tube Brazing

•

Heat Area 2 until braze temperature is attained,

moving torch up and down and rotating around

tube as necessary to heat tube evenly. Add braze

material to the joint while moving torch around

joint to flow braze material around circumference.

•

After braze material flows around joint, move

torch to heat Area 3. This will draw the braze

material down into the joint. The time spent

heating Area 3 should be minimal.

•

As with any brazed joint, overheating may be

detrimental to the final result.

‘Hipot’ (AC High Potential) Testing

Copeland Scroll compressors are configured with the

motor down and the pumping components at the top of

the shell. As a result, the motor can be immersed in

refrigerant to a greater extent than hermetic

reciprocating compressors when liquid refrigerant is

present in the shell. In this respect, the scroll is more like

semi-hermetic compressors that have horizontal motors

partially submerged in oil and refrigerant.

When Copeland Scroll compressors are hipot tested

with liquid refrigerant in the shell, they can show higher

levels of leakage current than compressors with the

motor on top. This phenomenon can occur with any

compressor when the motor is immersed in refrigerant.

The level of current leakage does not present any safety

issue. To lower the current leakage reading, the system

should be operated for a brief period of time to

redistribute the refrigerant to a more normal

configuration and the system hipot tested again. See