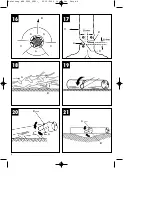

around 3-4 mm in the middle of the cutter rail (Fig.

9).

앬

Tighten the fixing screw of the chain wheel cover

(Fig. 7).

Caution:

All of the chain links must lie properly in

the guide groove of the cutter rail.

Notes on tensioning the chain:

The saw chain must be properly tensioned to ensure

safe operation. You can tell that the chain tension is

perfect if the saw chain can be lifted by around 3-4

mm in the middle of the cutter rail. As the saw chain

heats up during cutting and thus changes in length,

please check the chain tension every 10 minutes and

adjust it again as required. This applies in particular to

new saw chains. When you have finished working

slacken the chain again, as the chain will shorten

when it cools down. This will prevent the chain from

being damaged.

4.3 Saw chain lubrication

Caution:

Always disconnect the mains plug before

performing any checks or adjustments. Always wear

protective gloves when working on the chainsaw to

protect yourself against injury.

Caution:

Never operate the chain if it is not lubricated

with saw chain oil. Use of the chainsaw without saw

chain oil or if the oil level is below the “min” mark (Fig.

10/ Item B) will damage the chainsaw.

Caution:

Be aware of the temperature conditions:

different lubricants with completely different

viscosities are required at different ambient

temperatures. At lower temperatures you will need

low viscosity oils in order to achieve a sufficient

lubricating film. However, if the same low viscosity oil

is used during the summer it will become even thinner

due to the ambient temperatures alone, and as a

result the lubricating film could break down, causing

the chain to overheat and become damaged. In

addition, the chain oil would burn and produce

unnecessary pollutants.

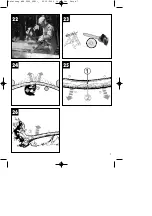

Filling the oil tank:

앬

Place the chainsaw on a flat surface.

앬

Clean the area around the oil tank cover (Fig.

10/Item A) and then clean the oil tank cover.

앬

Fill the tank with saw chain oil. In the process,

make sure that no dirt enters the tank, as this

could cause the oil nozzle to become blocked.

앬

Close the oil tank cover.

5. Operation

5.1 Connecting to the mains supply

앬

Connect the power cable to a suitable extension

cable. Make sure that the extension cable is

designed for the power rating of the chainsaw.

앬

Secure the extension cable as shown in Fig. 12 to

protect it against pulling forces and accidental

disconnection.

앬

Connect the extension cable to a professionally

installed safety mains outlet with ground contact.

We recommend using a cable with a bright and highly

visible color, e.g. red or yellow. This will reduce the

risk of accidentally damaging it with the chainsaw.

5.2 Switching on/off

Switching on

앬

Hold the chainsaw by the handles with both

hands as shown in Fig. 13 (thumbs under the

handles).

앬

Press and hold the safety lock-off (Fig. 1/Item 5).

앬

Switch on the chainsaw at the ON/OFF switch.

You can then release the safety lock-off.

Switching off

Release the ON/OFF switch (Fig. 1/Item 6).

The integrated brake will bring the running chainsaw

to a standstill within a very short space of time.

Always disconnect the mains plug when you stop

working, even if it is only for a short time.

Caution:

Always carry the saw by the front handle. If

the saw is plugged in and you carry it by the rear

handle (which is where the switches are located),

then there is a risk that you could accidentally press

the safety lock-off and the ON/OFF switch at the

same time, and the chainsaw could inadvertently start

up.

Explanation of the Operation/Overload indicator

(Fig. 2/Item 14):

Green LED:

The green LED comes on when the

device is in use.

Red LED:

The red LED comes on if the device

is overloaded. It does not go out until

the device is switched off and back

on again.

5.3 Safety devices – motor brake

The motor brakes the saw chain as soon as the

ON/OFF switch (Fig. 1/Item 6) is released or the

power supply is interrupted. This significantly reduces

GB

18

Anleitung NKS 2000_SPK1:_ 05.12.2006 16:13 Uhr Seite 18

Summary of Contents for 45.002.10

Page 4: ...4 6 4 5 8 9 7 B A Anleitung NKS 2000_SPK1 _ 05 12 2006 16 12 Uhr Seite 4...

Page 5: ...5 12 10 11 14 15 13 A B Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 5...

Page 7: ...7 24 22 23 26 25 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 7...

Page 87: ...RUS 87 12 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 87...

Page 102: ...102 T 1 2 3 2 4 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 102...