ER15-4-1600 Quick Operation Manual for Industrial Robot

第

23

页

operator and surrounding people, please be sure to set up a safety bar (and with interlocking doors and

other safety settings)!

Note: The GB11291.2-2013 standard is equivalent to the ISO 10218-2:2011 standard.

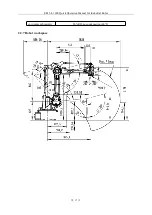

2.4.2 Robot installation method

The installation of the robot, especially the fixing of the base and the foundation, can bear the dynamic

load of the robot during acceleration and deceleration and the static weight of the robot and the fixture. In

addition, when the mounting surface of the robot is not flat, the robot may be deformed and its performance

may be affected.

The flatness of the robot installation should be less than 0.5mm.

The size of the base mounting interface is shown in Figure 2-6

:

Figure 2-6 Robot base dimensions

2.4.3 Ground installation

Ground installation requires the concrete foundation to be firm, the strength level and load-bearing

capacity should meet the relevant quality specifications, the thickness of the concrete should not be less

than the filling depth of the chemical bolts, and the effective range should completely cover the fixed

bottom plate to ensure the safety and reliability of the bottom plate installation. The concrete strength grade

C20/C25 is implemented with reference to the following specifications: GB50010-2010 "Specification for

Design of Concrete Structures" and GB/T50081-2002 "Test Methods for Mechanical Properties of Ordinary

Concrete".

Table 2-8 Parts list for robot fixing