Mechanical Operations and Maintenance Manual for Industrial Robot ER10-1600

34

Attention

The replacement of the timing belt involves the disassembly posture of the robot,

the selection of the timing belt and the zero calibration after replacement, and

special tools are needed in the process of disassembly and assembly. There are

potential safety hazards in the disassembly and assembly of the customer. If you

need to replace it, please contact the after-sales service department of our company.

4.5 Robot

M

aintenance and

U

se

A

rea

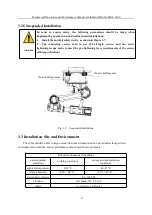

The maintenance area and use area of the mechanical unit are shown in Figure 4-4. The use area of the

robot can be adjusted according to the user's working environment.

1

、

The use area must have the following safety conditions

1

)

A safety fence and safety gate must be installed around the robot. If the safety gate is not opened, the

operator cannot enter the safety fence. An interlock switch, safety latch, etc. are set on the safety gate.

The robot will stop after opening the safety gate;

2

)

A safety carpet or photoelectric switch should be installed on the floor so that when the operator enters

the robot's range of motion, an alarm will be issued through the buzzer and photoelectric switch to

stop the robot from moving to ensure the safety of the operator;

3

)

The height of the safety fence is not less than 2 meters;

2

、

Qualification requirements and precautions for maintenance personnel:

1

)

To enter the safety fence, you must go through professional training;

2

)

When entering the robot's working area, it must be powered off and locked.

Fig. 4-4 Maintenance and Use Area

Maintenance area

Calibration area