150

P/N 120413

01/05

Saving Inspections

PresencePLUS

®

P4 EDGE

Banner Engineering Corp.

• Minneapolis, MN USA

www.bannerengineering.com • Tel: 763.544.3164

To display the Save window:

Click the

Save

button in the Menu toolbar. Options are explained in the following table.

NOTE: The Save window is also displayed whenever the Sensor prompts the user to save something.

-----------------------------------------------------------

-------------------------------------------------------------

Inspection (.inp) Files

Inspection files can be saved either to the Sensor or to the PC. Inspections must be saved to the Sensor in order to be run.

A copy of the inspection may also be saved to the PC to serve as a backup.

An inspection (.inp) file contains the reference image, image parameters, and inspection parameters:

•

The reference image is the image selected in the Setup screen.

•

Image parameters are the programmed values that were used by the Sensor to acquire the inspection image. These values

include gain, exposure time, and trigger setup.

•

Inspection parameters include Location tools, Vision tools, and Analysis tools and their associated parameters.

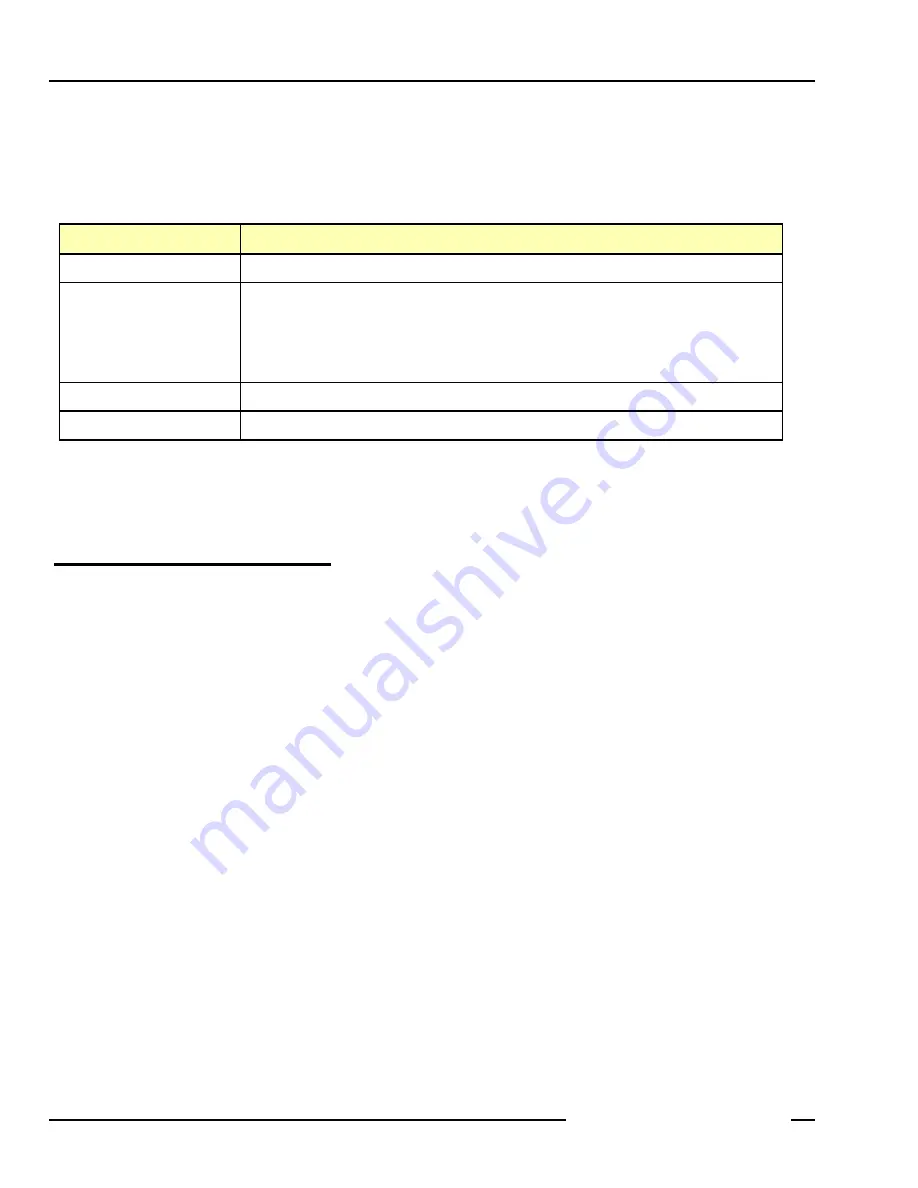

Save Window Options

Option

Description

Save in Sensor

The Sensor will prompt the user to select one of 12 Sensor locations.

Save in Inspections Folder

If an occupied location is selected, the selected filename appears in the

Filename

field. The file

being saved overwrites the selected file.

To clear a location, delete the file on the Sensor tab. See

Selecting or Deleting Inspections from

Save the file in any folder on the PC, or create new subfolders.

Save as an .inp

Saving as an

.inp

saves the entire inspection.

Save as a .bmp

Saving as a

.bmp

saves only the current image. This is available only when saving to the PC.

Summary of Contents for PresencePlus P4

Page 1: ...Printed in USA P N 120413...

Page 3: ...This User s Manual reflects Sensor Firmware Version 1 0 0 and GUI Software Version 2 0 2...

Page 4: ......

Page 8: ......

Page 180: ......

Page 181: ......