15

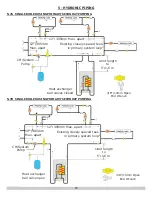

5 - HYDRONIC PIPING

5-7A SINGLE BOILER USING PRIMARY/SECONDAY PUMPING

12"/305mm Max. apart

12"/305mm

Max. apart

Limit length

to

5'/1.6 m

CH/System

Pump

Heat exchanger

ball valve open

Heat exchanger

ball valves closed

3/8"/10mm Open

End Wrench

5-7B SINGLE BOILER USING PRIMARY/SECONDAY PUMPING

CH/System

Pump

12"/305mm

Max. apart

12"/305mm Max. apart

Existing closely spaced tees

in primary system loop

Limit length

to

5'/1.6 m

3/8"/10mm Open

End Wrench

Existing closely spaced tees

in primary system loop

Summary of Contents for SSC Olsen OLSSC-050

Page 46: ...46 13 TROUBLE SHOOTING ...

Page 53: ...53 14 WIRING DIAGRAM 14 1 Connection Diagram ...

Page 54: ...54 14 WIRING DIAGRAM 14 2 Schematic Diagram of Ladder Form ...

Page 71: ...71 Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 72: ...ECR International Inc 2201 Dwyer Avenue Utica NY 13504 4729 web site www ecrinternational com ...