SHRED 'N' VAC

®

Operator's Manual

MODEL

ES-210

Serial Number 05001001 - 05999999

X753000720

03/03

X7531130200

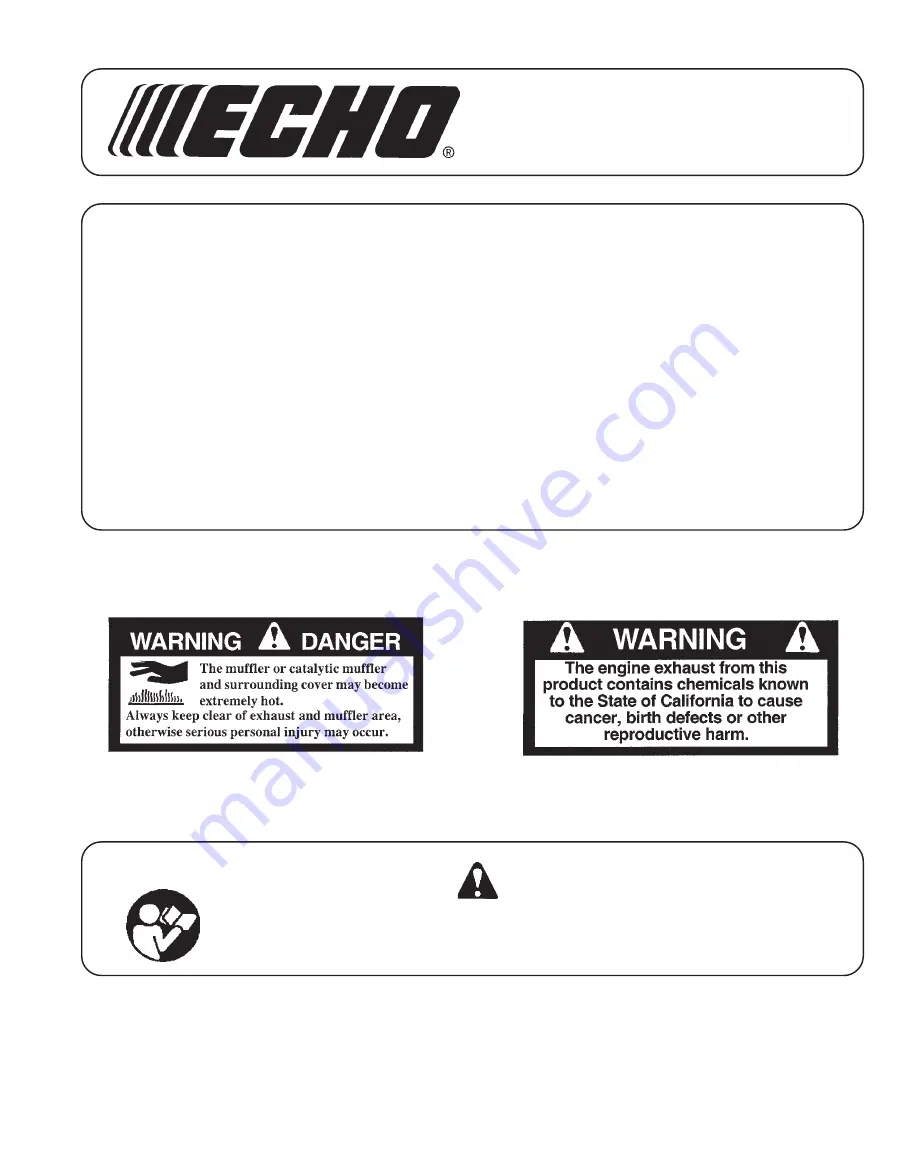

WARNING

DANGER

Read rules for safe operation and all instructions carefully. ECHO provides this

Operator's Manual which must be read and understood for proper and safe operation.