24

EN

EBS Ink-Jet Systeme

20080908#3.0

EN

air. Wait until the micro compres-

sor stops working.

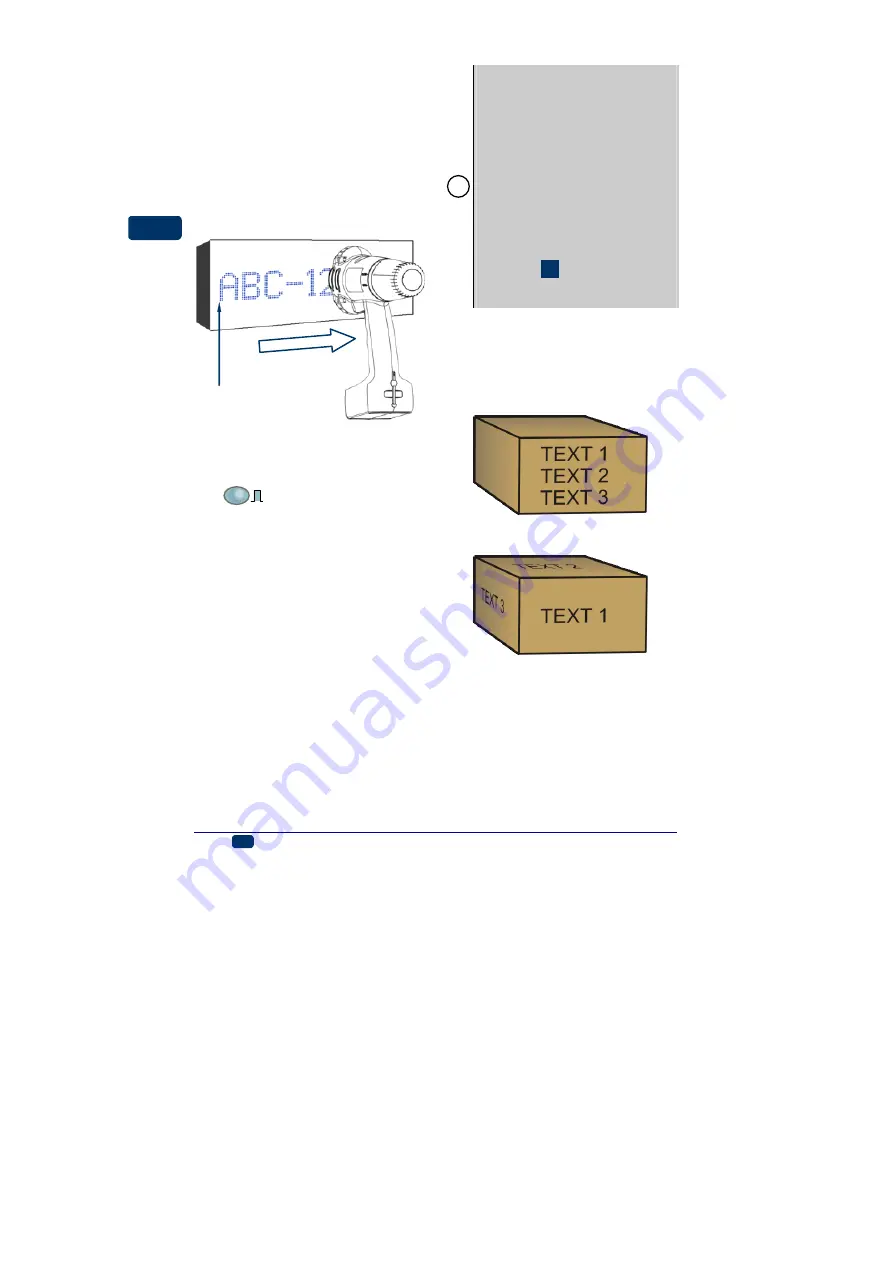

3. Move the head of the printer to

an object to be labelled to ensure

that drive rolls

touch the

surface of the object.

4. Press print release button

release button) and move the

printer along the object ensuring

that the drive rolls roll at a uni-

form speed.

here printing is released

with the release button

the printer moves along the object

5. Make successive prints by press-

ing release button

6. After all prints have been made

press and then release button

ON/OFF

goes out.

If the

Stop printing method

and you

press button

will

flash. This means that you have

pressed release button

but not

finished printing. In such a case

you can finish printing or aban-

don printing by pressing button

once again. If the

Stop print-

ing method

parameter is set to

Immediate stop

the printer will

not remind you about the unfin-

ished printing.

The

Stop printing method

parameter is available in the

Advance

tab sheet after the

Adv. options

box has been

ticked).

!

If the printer has been idle for longer

than about 30 minutes, the nozzle

outlets might become covered with

dry ink. Before you start printing

make a trial printing or use the rinse-

the-nozzles function for a while in

order to clear the nozzles - see

If you label objects whose height is

smaller than 60 mm (the distance

between the rolls is 60 mm), make

sure that at least lower roll

signed for synchronising printing)

touches the object being labelled -

see figure

. The rule does not

apply if printing is synchronised by

the internal generator.

Line Printing

Line printing is used to print a few

texts manually in a fast way:

•

on consecutive lines as shown in

the figure below:

•

or in different places on an object

as shown in the figure below:

Create texts to be printed in the fol-

lowing way:

1. Create

TEXT 1

in the text edit

line. Every line of the text can

have all the text elements (such

as variable fields, various fonts,

etc.) described previously.