Operating instructions

W3G800-NB86-43

Translation of the original operating instructions

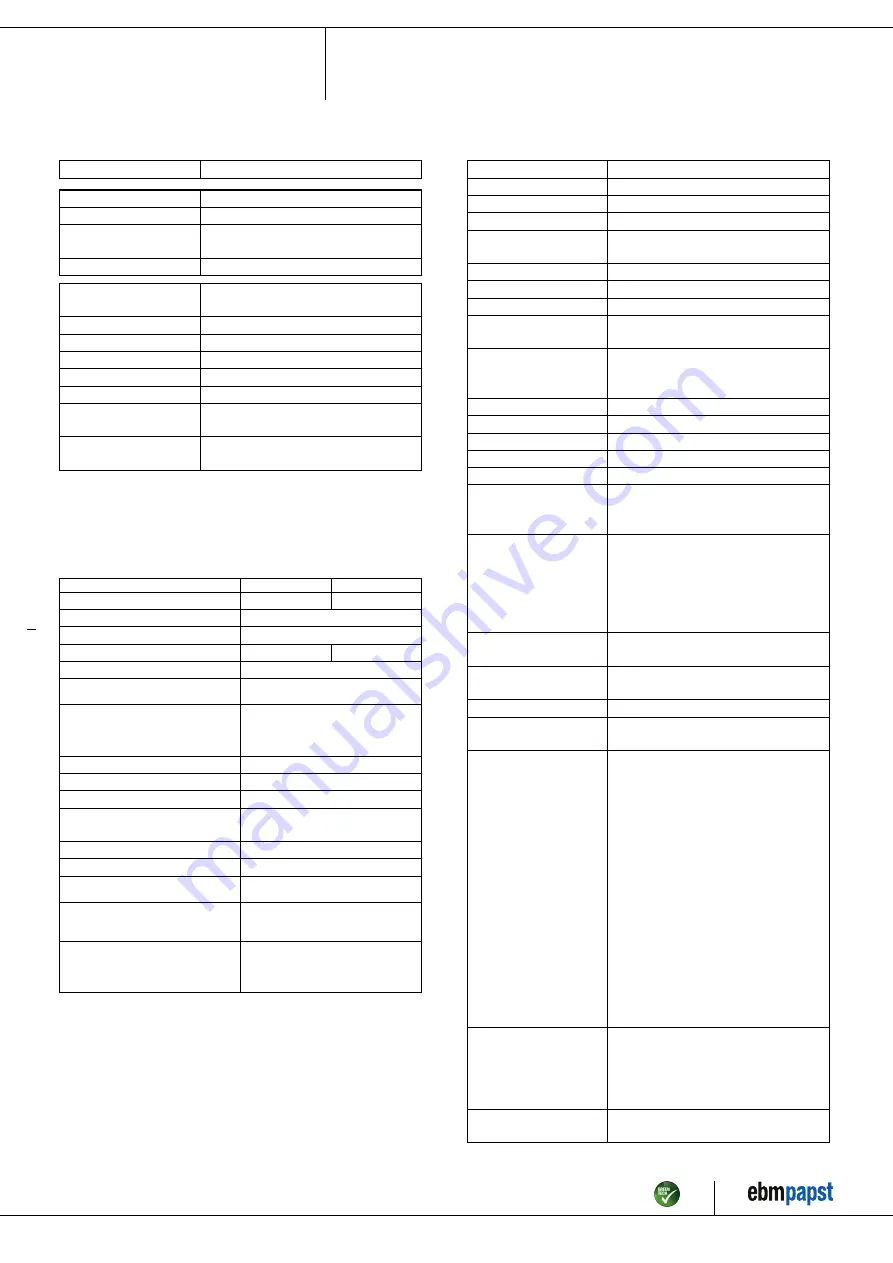

3.2 Nominal data

Motor

M3G112-EA

Phase

1~

Nominal voltage / VAC

230

Nominal voltage

range / VAC

200 .. 277

Frequency / Hz

50/60

Method of obtaining

data

ml

Status

prelim.

Speed (rpm) / min

-1

520

Power consumption / W

250

Current draw / A

1.1

Max. back pressure / Pa

60

Min. ambient

temperature / °C

-40

Max. ambient

temperature / °C

40

ml = Max. load · me = Max. efficiency · fa = Free air

cs = Customer specification · ce = Customer equipment

Subject to change

3.3 Data according to Commission Regulation (EU) 327/

2011

Actual

Req. 2015

01 Overall efficiency η

es

/ %

54.5

29.8

02 Measurement category

A

03 Efficiency category

Static

04 Efficiency grade N

64.7

40

05 Variable speed drive

Yes

06 Year of manufacture

The year of manufacture is specified on the

product's rating label.

07 Manufacturer

ebm-papst Mulfingen GmbH & Co. KG

Amtsgericht (court of registration) Stuttgart

· HRA 590344

D-74673 Mulfingen

08 Type

W3G800-NB86-43

09 Power consumption P

ed

/ kW

0.24

09 Air flow q

v

/ m³/h

8780

09 Pressure increase total p

sf

/

Pa

48

10 Speed (rpm) n / min

-1

520

11 Specific ratio

*

1.00

12 Recycling/disposal

Information on recycling and disposal is

provided in the operating instructions.

13 Maintenance

Information on installation, operation and

maintenance is provided in the operating

instructions.

14 Additional components

Components used to calculate the energy

efficiency that are not apparent from the

measurement category are detailed in the

CE declaration.

*

Specific ratio = 1 + p

fs

/ 100 000 Pa

Data obtained at optimum efficiency level. The ErP data is determined using a motor-impeller

combination in a standardized measurement setup.

3.4 Technical description

Weight

0.001 kg

Size

800 mm

Motor size

112

Rotor surface

Painted black

Electronics housing

material

Die-cast aluminum, painted black

Impeller material

PP plastic

Fan housing material

PP plastic

Material guide vanes

PP plastic

Guard grille material

Steel, coated with black plastic (RAL

9005)

Internal diffuser

material including

cover

PP plastic

Number of blades

5

Airflow direction

V

Direction of rotation

Clockwise, viewed toward rotor

Degree of protection

IP55

Insulation class

"F"

Moisture (F) /

Environmental (H)

protection class

H2

Ambient temperature

note

If there is a risk of ice formation, the fan

is only to be operated with a heating tape

in the fan housing. Further information

can be obtained from ebm-papst. As fan

only suitable for use with industrial

evaporators

Installation position

Shaft horizontal or rotor on bottom; rotor

on top on request

Condensation

drainage holes

On rotor side

Mode

S1

Motor bearing

Ball bearing with low-temperature

lubricant; (sealed)

Technical features

- Output 10 VDC, max. 10 mA

- Operation and alarm display

- Tach output

- Alarm relay

- Integrated PID controller

- Power limiter

- Motor current limitation

- PFC, active

- RS-485 MODBUS-RTU

- Soft start

- Control input 0-10 VDC / PWM

- Control interface with SELV potential

safely disconnected from the mains

- Thermal overload protection for

electronics/motor

- Line undervoltage / phase failure

detection

Touch current

according to IEC

60990 (measuring

circuit Fig. 4, TN

system)

<= 3.5 mA

Motor protection

Thermal overload protector (TOP)

internally connected

Item no. 55755-5-9970 · ENU · Change 205336 · Approved 2020-07-16 · Page 6 / 13

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com