Operating instructions

D3G318-AA35-01

Translation of the original operating instructions

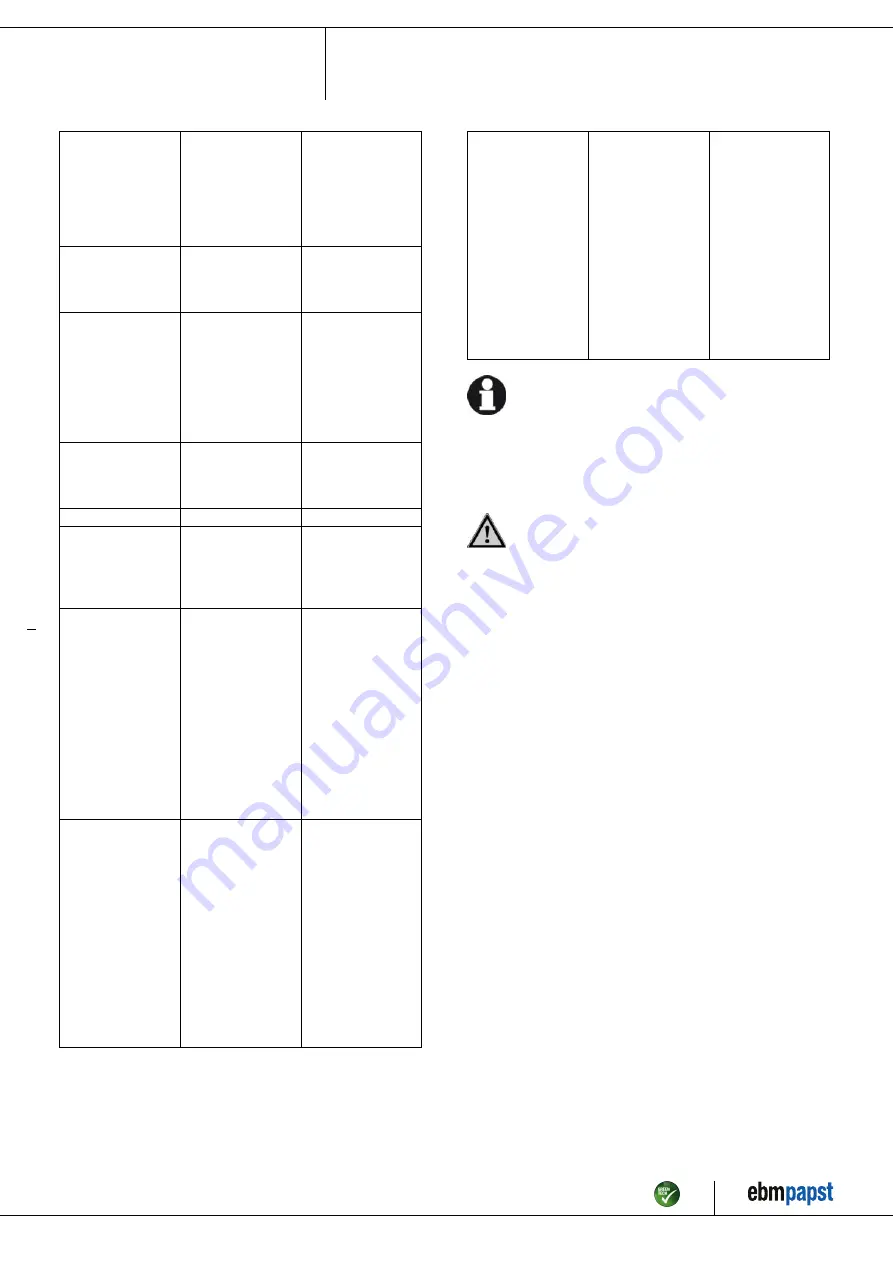

Impeller not

running smoothly

Imbalance in rotating

parts

Clean the device;

replace it if imbalance

persists after cleaning.

Make sure no

weight clips are

removed during

cleaning.

Motor not turning

Mechanical blockage

Switch off, isolate

from supply and

remove mechanical

blockage.

Line voltage faulty

Check line voltage,

restore power supply.

Attention! The error

message resets

automatically.

Device restarts

automatically without

warning.

Faulty connection

Isolate from supply,

correct connection;

see connection

diagram.

Broken motor winding Replace device

Thermal overload

protector activated

Allow motor to cool

off, locate and rectify

cause of error,

release restart lockout

if necessary

Deficient cooling

Improve cooling. Let

the device cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

Ambient temperature

too high

Reduce the ambient

temperature. Let the

device cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

Impermissible point of

operation (e.g. back

pressure too high)

Correct the operating

point. Let the device

cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

In the event of further malfunctions, contact ebm-papst.

6.1 Cleaning

To ensure a long service life, check the fans regularly for proper

operation and soiling. The frequency of checking is to be adapted

accordingly depending on the degree of soiling.

DANGER

Risk of injury from rotating fan.

→ Only clean when not in motion. Do not disconnect the fan

from the power supply, just switch it off via the control input.

This will prevent start-up of the fan.

;

Dirt deposits on the motor housing can cause overheating of the motor.

;

Soiling of the impeller can cause vibration that will shorten the service

life of the fan.

;

Severe vibration can destroy the fan.

;

In such cases, switch off the fan immediately and clean it.

;

The preferred method of cleaning is dry cleaning, e.g. using

compressed air.

;

Do not use aggressive cleaning agents!

NOTE

Damage to the device during cleaning

Malfunction possible

→ Do not clean the device using a water jet or high-pressure

cleaner.

→ Do not use any acid, alkali or solvent-basedcleaning

agents.

→ Do not use any pointed or sharp-edged objects for cleaning

;

Completely remove any cleaning agents used.

;

If severe corrosion is visible on load-bearing or rotating parts, switch

off the device immediately and replace it.

;

Repair of load-bearing or rotating parts is not permitted!

;

Operate the fan for 2 hours at maximum speed so that any water that

has ingressed can evaporate.

;

If cleaning does not eliminate vibrations, the fan may need to be

rebalanced. To have it rebalanced, contact ebm-papst.

;

The fan is equipped with maintenance-free ball bearings. The lifetime

lubrication of the ball bearings is designed for a service life of 40,000

hours.

;

If bearing replacement is necessary after that period, contact ebm-

papst.

;

Adapt the maintenance intervals to the actual level of dust exposure.

Item no. 50384-5-9970 · ENU · Change 210923 · Approved 2020-03-14 · Page 10 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com