Part Number

Operating Instructions

Item no. LS-122.

Revision 002

Release 18/02/2016

Page 5 of 12

ebm-papst A&NZ Pty Ltd

10 Oxford Road · Laverton North VIC 3026 · Phone +61 (03) 9360 6400 · Fax +61 (03) 9360 6464

ABN 33 115 927 556

NSW Phone +61 (02) 9827 6400 · NSW Fax +61 (02) 9827 6464 · NZ Phone +64 (09) 525 0245 · NZ Fax +64 (09) 525 0246

[email protected] · www.ebmpapst.com.au

AF1250-001

AFFB1250-00

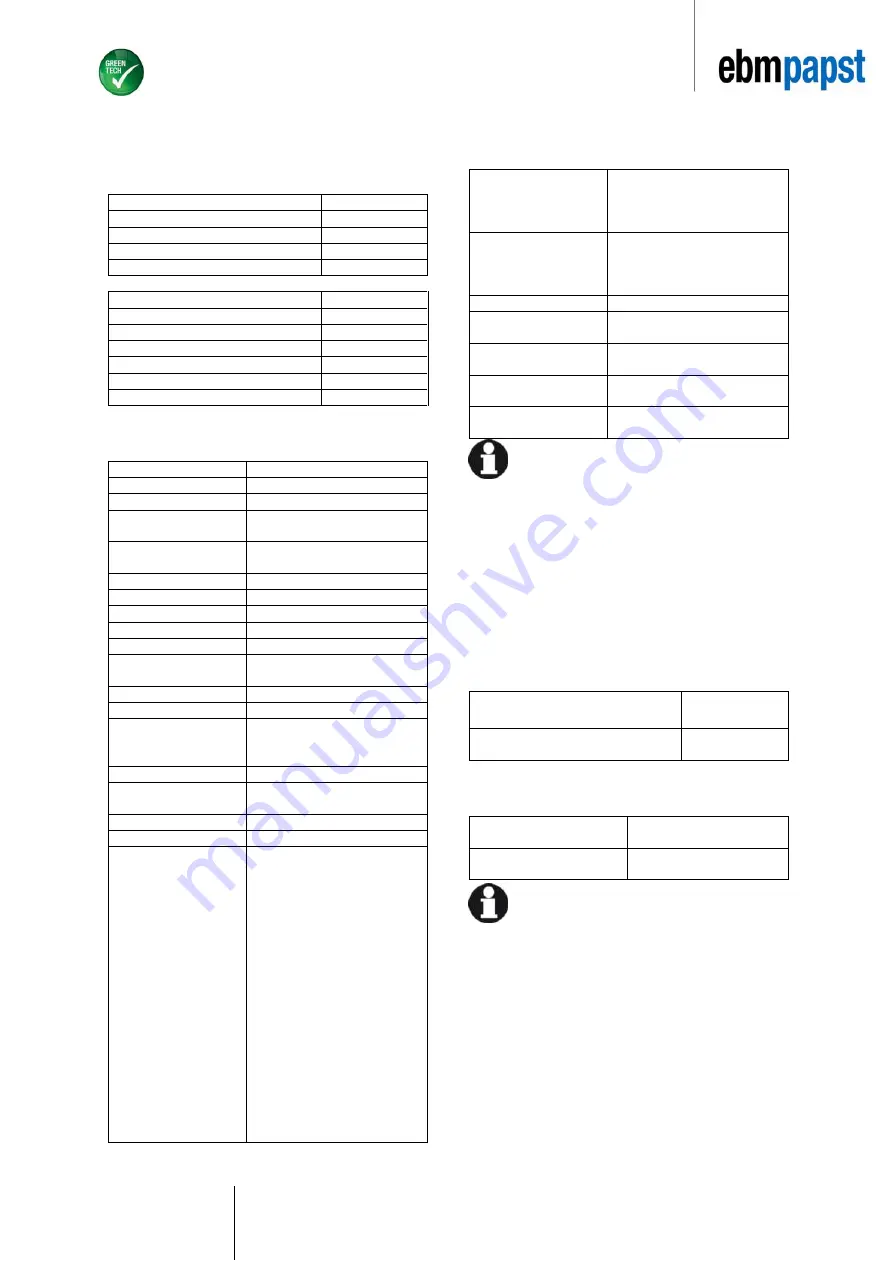

3.2

Nominal data

Motor

M3G150-NA

Phase

3~

Nominal Voltage / VAC

400

Nominal voltage range / VAC

380 .. 480

Frequency / Hz

50/60

Method of obtaining data

maximum load

Speed / min

-1

548

Power consumption / W

1800

Current draw / A

2.6

Max. Back pressure / Pa

78

Min. ambient temperature / °C

-25

Max. ambient temperature / °C

60

Subject to change

3.3

Technical description

Mass

118 kg

Size

1250 mm

Rotor surface

Painted black

Electronics housing

material

Die-cast aluminium, painted

black

Blade material

Die-cast aluminium, painted

black

Housing material

Galvanised steel

Guard grille material

Steel phosphate

Number of blades

3

Blade pitch

0º

Airflow direction

“A”

Direction of rotation

Counter clockwise, viewed

toward rotor

Degree of protection

IP 55

Insulation class

“F”

Moisture (F) /

Environmental (H)

protection class

F5

Installation position

Shaft horizontal or rotor on top

Condensate drainage

holes

On stator side

Mode

S1

Motor bearing

Ball bearing

Technical features

-

Output 10 VDC, max. 10 mA

-

Output 20 VDC, max. 50 mA

-

Output for slave 0-10 V

-

Input for sensor 0-10 V or 4-20

mA

-

External 24V input (parameter

setting)

-

External release input

-

Alarm relay

-

Integrated PID controller

-

Power limiter

-

Motor current limitation

-

PFC, passive

-

RS-485 MODBUS-RTU

-

Soft start

-

Control input 0-10 VDC/PWM

-

Control interface with SELV

potential safely disconnected

from the mains

-

Thermal overload protection for

electronics/motor

-

Line under voltage / phase

failure detection

Touch current

according to IEC 60990

(measuring circuit Fig.

4, TN system)

<= 3.5 mA

Electrical hook-up

Via terminal box

Motor protection

Reverse polarity and locked-rotor

protection

Protection class

I (with customer connection of

protective earth)

Conformity with

standards

EN 61800-5-1, CE

Approval

EAC; UL 1004-7 + 60730; C22

No.77 + CAN/CSA-E60730-1

With regard to cyclic speed loads, note that the

rotating parts of the device are designed for a

maximum of one million load cycles. If you have

specific questions, consult ebm-papst A&NZ for

support.

3.4

Mounting data

Secure the screws against unintentional loosening (e.g. use

self-locking screws).

Any further mounting data required can be taken from the

product drawing.

3.5

Transport and storage conditions

Use the device in accordance with its degree of protection.

Max. permissible ambient temp. for

motor (transport/storage)

+ 80 °C

Min. permissible ambient temp. for

motor (transport/storage)

- 40 °C

3.6

Electromagnetic compatibility

EMC immunity to

interference

According to EN 61000-6-2

(industrial environment)

EMC interference emission

According to EN 61000-6-4

(industrial environment)

If several devices are switched in parallel on the

supply side so that the line current of the

arrangement is in the range of 16 – 75 A, then this

arrangement conforms to IEC 61000-3-12 provided

that the short-circuit power S

sc

at the connection point

of the customer system to the public power system is

greater than or equal to 120 times the rated output of

the arrangement. It is the responsibility of the

installation engineer or operator/owner of the device

to ensure, if necessary after a consultation with the

network operator, that this device is only connected to

a connection point with a S

sc

value that is greater

than or equal to 120 times the rated output of the

arrangement.