13

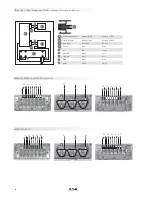

6.3

Closing flood light

Fig 10 ... 11

Remove all foreign bodies from the device.

– Pay attention to the correct fit of the enclosure top part and the seals.

– All seals must be clean and undamaged.

– The flood light may not be damaged.

– Tighten all enclosure combi-screws evenly diagonally (test torque see

technical data).

Mind! Overtightening might impair the pull-relief effect!

7

Taking into operating

Prior to taking the apparatus into operation, the tests specified in the

relevant national regulations will have to be carried out.

Apart from that, the correct functioning and installation of the apparatus

in accordance with these operating instructions and other applicable

regulations will have to be checked (IEC/EN 60079-14).

Please observe the following before closing the flood light:

– All seals must be clean and undamaged.

– The flood light may not be damaged.

Improper installation and operation of the lamp leads to loss of the

guarantee.

8 Maintenance/Servicing

The required maintenance intervals are set according to their

application and should therefore be determined depending on the

conditions of use.

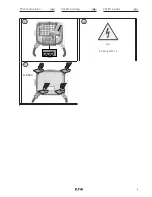

Warning against electric shock.

Before opening the enclosure make sure that the apparatus is

disconnected from the voltage, or take the appropriate protective

measures.

Make sure that there is no explosive ambient atmosphere when

opening the equipment.

The relevant national regulations which apply to the maintenance/

servicing of electrical apparatus in explosive atmospheres, shall be

observed (IEC/EN 60079-17).

8.1

General Maintenance / Inspection

Within the scope of the maintenance / inspection, especially those parts

on which the type of protection depends must be checked for damage, e.g.:

– Protective hoses over the connecting cables.

– Housing and protective glass for any cracks or damages.

– Seals for the flood light and cable glands.

– Cable entries must be free from corrosion!

– Terminals and blanking plugs must be checked for secure fitting.

If during servicing repairs prove to be necessary, section 9 of these

operating instructions will have to be observed.

9

Repairs / Overhaul / Modification

Repairs that affect the explosion protection, may only be carried

out by COOPER CROUSE-HINDS or a qualified electrician (Compe-

tent person) in compliance with the applicable national rules

(IEC/EN 60079-19).

For replacement and repair only original parts from COOPER

CROUSE HINDS-/ EATON may be used.

Should the flameproof enclosure be damaged, only a replacement

will be permitted. In case of doubt, the respective apparatus will

have to be returned to COOPER CROUSE-HINDS / EATON for repair.

Modifications to the device or changes of its design are not permitted.

They shall be used for their intended purpose and in perfect and

clean condition.

10 Disposal/Recycling

When the apparatus is disposed of, the respective national regulations on

waste disposal will have to be observed.

In case of disposal you can obtain additional information from your Cooper

Crouse-Hinds / EATON branch.

Subject to modifications or supplement of the product range.

Explosion protected flood light type: PXLED

GB

Summary of Contents for PXLED

Page 18: ...18 Notizen Notes Remarques ...

Page 19: ...19 Notizen Notes Remarques ...