112

Eaton Power Xpert 9395 UPS Installation and Operation Manual 164201725—Rev 15

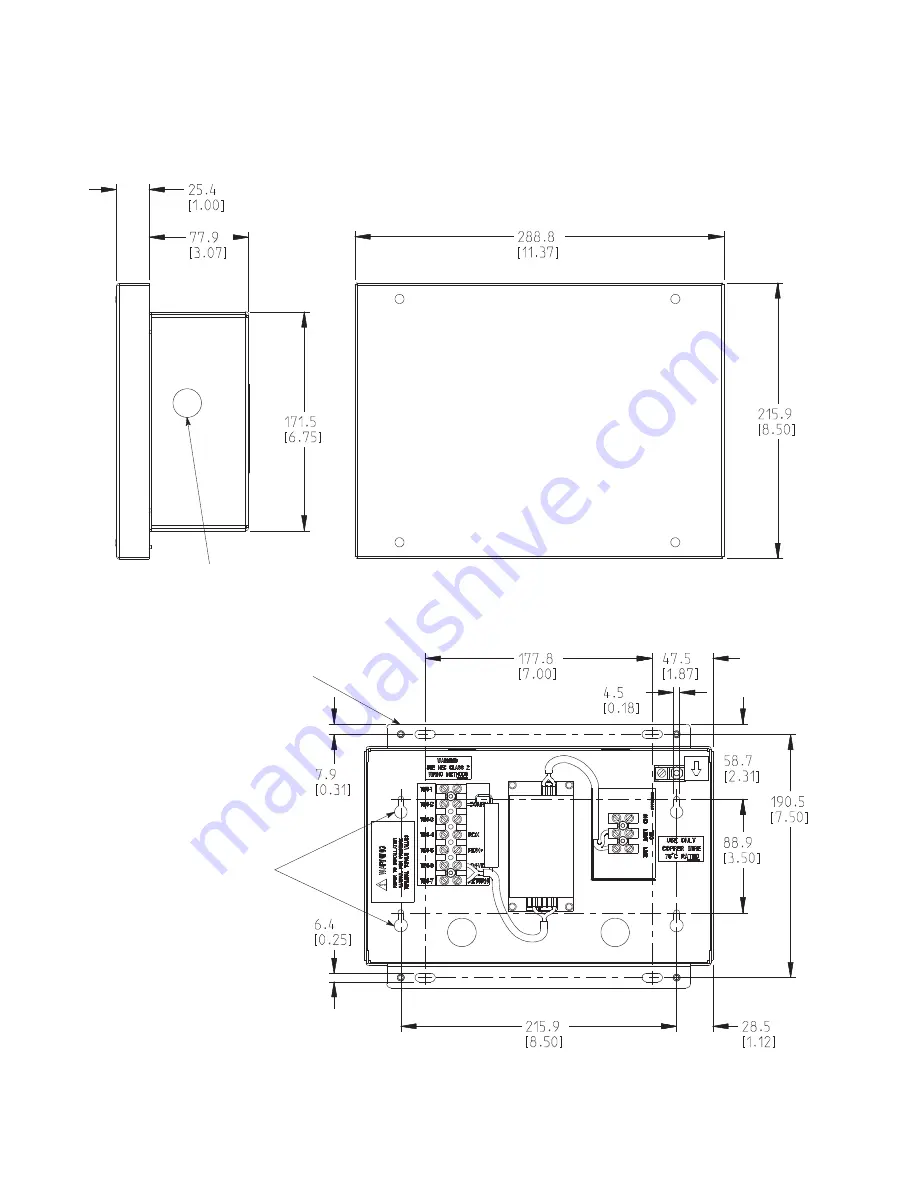

Figure 69. Relay Interface Module II Dimensions

Knockouts Provided

on Five Surfaces

Surface Mount using #10 Pan

Head Screws for Hanging.

(Mount with vent holes facing up.)

Flush Mount using #10 Pan

Head Screws. (Mount with vent holes

facing up.)

Dimensions are in millimeters [inches].

Summary of Contents for Power Xpert 9395

Page 8: ......

Page 269: ...16420172515 164201725 15 ...